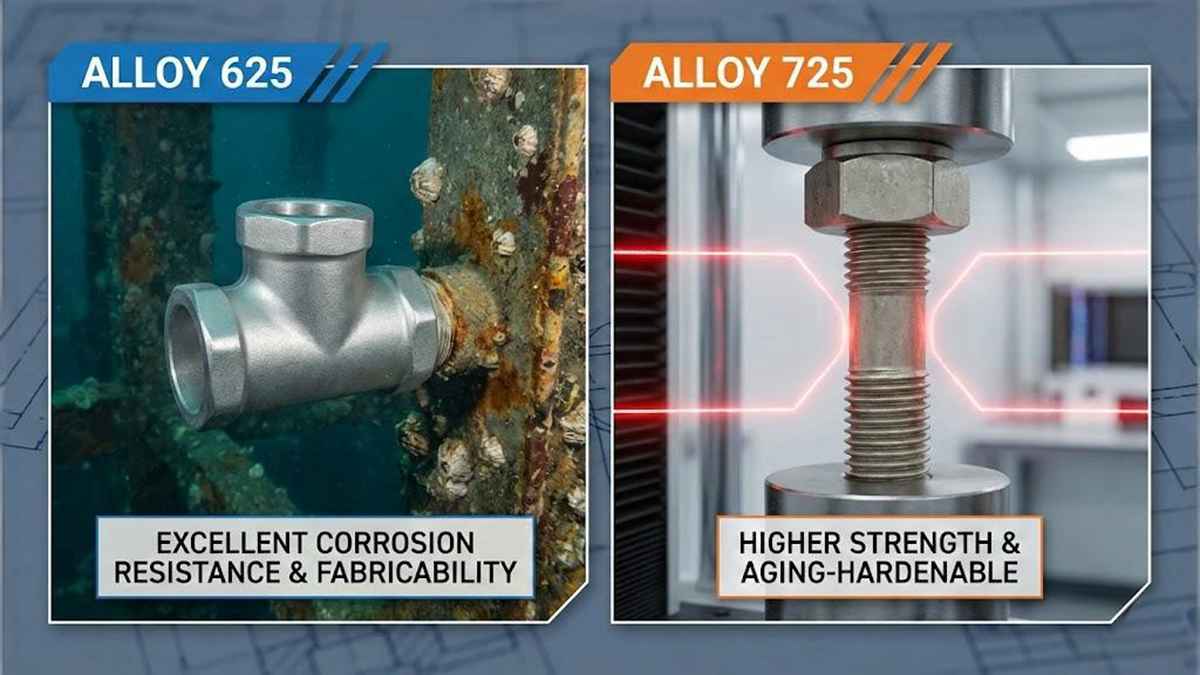

While they share a nearly identical genetic code regarding corrosion resistance, the distinction lies entirely in how they handle mechanical stress.

Chemical Composition

To understand the difference, we must first look at the chemistry. Alloy 625 is a nickel-chromium-molybdenum alloy containing niobium. This combination delivers outstanding resistance to pitting and crevice corrosion.

Alloy 725 (UNS N07725) is essentially Alloy 625 with a specific modification. Metallurgists took the proven corrosion-resistant base of 625 and added small, precise amounts of Titanium (Ti) and Aluminum (Al).

-

Alloy 625: Strengthened primarily by the stiffening effect of molybdenum and niobium in the nickel-chromium matrix (Solid Solution Strengthening).

-

Alloy 725: Strengthened by the precipitation of microscopic gamma-prime and gamma-double-prime phases during heat treatment (Precipitation Hardening).

The Core Difference: Yield Strength

If corrosion resistance is the shield, yield strength is the muscle. This is where the difference between 625 and 725 alloy becomes undeniable.

Alloy 625 is tough, but in its annealed state, its yield strength is typically around 60-70 ksi (414-483 MPa). To make it stronger, it must be “cold worked” (physically compressed or drawn), which limits the shapes and sizes you can produce.

Alloy 725 changes the game. Because of the added Titanium and Aluminum, it can be heat-treated (aged) to achieve ultra-high strength without needing cold work. Alloy 725 routinely achieves yield strengths exceeding 120 ksi (827 MPa)—roughly double that of annealed Alloy 625.

This makes Alloy 725 the superior choice for large, complex sections that require high strength but are too thick to be effectively cold-worked.

مقاومة التآكل

Engineers often fear that increasing strength means sacrificing corrosion resistance. Fortunately, with these two alloys, that isn’t the case.

Because the base chemistry (high Nickel and Molybdenum) remains consistent, Alloy 725 retains essentially the same corrosion resistance as Alloy 625. Both alloys offer exceptional resistance to:

-

Seawater and marine environments.

-

Pitting and Crevice corrosion.

-

Sulfide stress cracking (SSC).

This unique combination puts Alloy 725 in a distinct category: it offers the corrosion resistance of 625 with the strength of Alloy 718.

Application Scenarios: When to Use Which?

Choosing between them usually comes down to the mechanical load of the application.

Choose Alloy 625 when:

-

You need excellent fabricability and weldability.

-

The application involves cladding (overlaying) or sheet metal components like exhaust ducts.

-

Extreme yield strength is not the primary requirement.

Choose Alloy 725 when:

-

You are designing fasteners, hangers, or landing nipples for Sour Gas service (NACE MR0175).

-

You need the material to withstand massive tensile stress in marine environments.

-

The component is a large section bar or forging where cold working is impossible.

الأسئلة الشائعة (FAQs)

Q1: Can Alloy 725 be welded as easily as Alloy 625?

While both can be welded, Alloy 625 is generally considered to have superior weldability and is often used as a filler metal itself. Alloy 725 can be welded, but because it is an age-hardenable alloy, it typically requires post-weld heat treatment to restore its high-strength properties in the heat-affected zone.

Q2: Is Alloy 725 magnetic?

No. Like Alloy 625, Alloy 725 is a nickel-based superalloy and is non-magnetic in all conditions. This makes both alloys suitable for applications where magnetic permeability must be minimized, such as in sensitive electronic housings or submarine components.

Q3: Why is Alloy 725 more expensive than 625?

The cost difference stems from processing complexity. While the raw material costs are comparable, Alloy 725 requires precise vacuum melting and extended heat-treatment cycles (solution annealing plus two-step aging) to achieve its mechanical properties. Additionally, Alloy 625 is produced in much larger volumes, offering economies of scale.