Selecting the right material for highly corrosive industrial applications often leads to a comparison between two powerhouse nickel-iron-chromium alloys: Alloy 20 (UNS N08020) and Incoloy 825 (UNS N08825). While both are engineered to withstand aggressive media, their metallurgical nuances dictate their suitability for specific chemical processes. This article explores the technical differences, performance benchmarks, and selection criteria for these alloys.

Alloy 20 vs Incoloy 825 comparison

From a metallurgical perspective, both materials are “super-austenitic” or high-nickel alloys designed to bridge the gap between standard 300-series stainless steels and high-cost nickel-base superalloys. However, their stabilizing elements and nickel content set them apart.

Alloy 20, often referred to as “Carpenter 20,” is stabilized with Niobium (Columbium). This addition prevents intergranular corrosion by inhibiting carbide precipitation during welding. On the other hand, Incoloy 825 is stabilized with Titanium, which serves a similar purpose but behaves differently in oxidizing environments.

Chemical & Mechanical Property Comparison

| الممتلكات | Alloy 20 (UNS N08020) | Incoloy 825 (UNS N08825) |

| Nickel (Ni) % | 32.5 – 38.0 | 38.0 - 46.0 |

| Chromium (Cr) % | 19.0 – 21.0 | 19.5 - 23.5 |

| Copper (Cu) % | 3.0 – 4.0 | 1.5 - 3.0 |

| Molybdenum (Mo) % | 2.0 – 3.0 | 2.5 - 3.5 |

| Stabilizer | النيوبيوم (Nb) | التيتانيوم (Ti) |

| Tensile Strength (ksi) | 80 min | 85 min |

| Yield Strength (0.2% Offset, ksi) | 35 min | 35 min |

While Incoloy 825 boasts a higher nickel content—imparting superior resistance to chloride-induced stress corrosion cracking (SCC)—Alloy 20 features higher copper levels, which is the secret to its legendary performance in reducing acids.

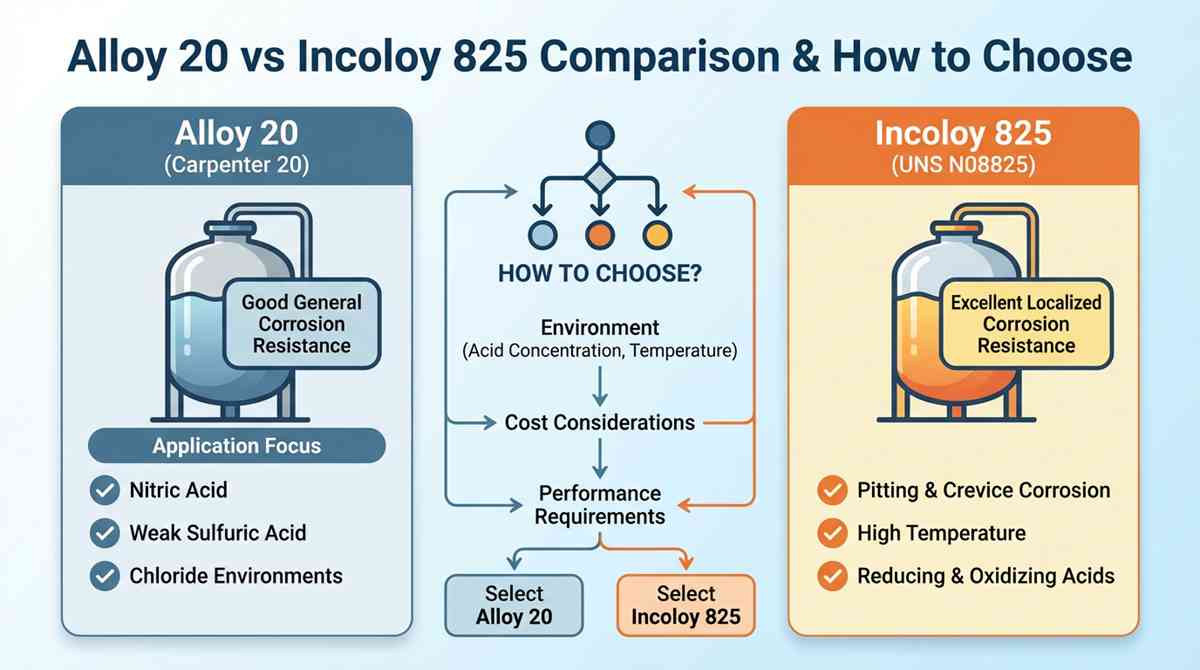

Alloy 20 vs Incoloy 825 how to choose

The decision between Alloy 20 and Incoloy 825 is rarely about which is “better,” but rather which is “right” for the specific environmental chemistry.

-

Chloride Resistance: If your application involves high levels of chlorides (such as seawater or brackish water) where pitting and crevice corrosion are primary concerns, Incoloy 825 is usually the safer bet. Its higher Molybdenum and Nickel content provides a higher Pitting Resistance Equivalent Number (PREN).

-

Temperature Limits: Incoloy 825 is typically rated for service up to 1000∘F (540∘C), though its mechanical properties remain stable at cryogenic temperatures as well. Alloy 20 is frequently utilized in processes where temperatures remain below 800∘F.

-

Cost Efficiency: Historically, Alloy 20 has been the more cost-effective choice for chemical processing plants focusing strictly on sulfuric acid. However, since Incoloy 825 is more widely used in the Oil & Gas sector, global availability can sometimes make 825 more accessible despite the higher nickel content.

Alloy 20 vs 825 for sulfuric acid service

Sulfuric acid (H2SO4) is the primary battleground for these two alloys. Alloy 20 was specifically developed for sulfuric acid service. Its high copper content (3.0−4.0%) allows it to maintain a protective film in the presence of this reducing acid, even at concentrations that would rapidly destroy 316L stainless steel.

-

Alloy 20 Performance: It is often the “gold standard” for 20% to 40% sulfuric acid at elevated temperatures. It shows excellent resistance across the entire concentration range up to approximately 150∘F (65∘C).

-

Incoloy 825 Performance: While 825 is also excellent in H2SO4, it is frequently preferred when the acid is “mixed”—containing oxidizing salts (like ferric or cupric ions) or chlorides. In high-temperature, highly concentrated sulfuric acid (>90%), both alloys begin to reach their limits, often requiring more specialized materials like Hastelloy® C276.

In summary, for pure, “clean” sulfuric acid loops, Alloy 20 provides the most reliable longevity. For complex, contaminated chemical streams, Incoloy 825 offers a broader range of protection.

أسئلة وأجوبة ذات صلة

Q1: Is Alloy 20 more resistant to stress corrosion cracking (SCC) than Incoloy 825? Generally, No. While Alloy 20 is resistant to SCC, the higher nickel content in Incoloy 825 (38−46%) provides a slightly more robust defense against chloride-induced stress corrosion cracking in extreme environments.

Q2: Can Alloy 20 be used in nitric acid service? Yes. Due to its chromium content, Alloy 20 has good resistance to oxidizing acids like nitric acid. However, if the environment is strictly oxidizing, Incoloy 825 or even Alloy 600 might be evaluated depending on the concentration and temperature.

Q3: Which alloy is easier to weld? Both alloys have excellent weldability. Alloy 20’s Niobium stabilization makes it very resistant to intergranular corrosion in the heat-affected zone (HAZ). Using the correct filler metal (e.g., ER320LR for Alloy 20 and ERNiCrMo-3 for 825) is critical to maintaining corrosion resistance.