Choosing the right nickel-based superalloy is critical for aerospace, power generation, and chemical processing. Two of the most prominent contenders are هاستيلوي X و إنكونيل 718. While both offer exceptional performance, they serve very different mechanical and thermal roles.

Hastelloy X vs 718 Comparison

At the molecular level, the fundamental difference between هاستيلوي X و إنكونيل 718 lies in their strengthening mechanisms. Hastelloy X is a تقوية المحلول الصلب المعزز alloy (predominantly Nickel-Chromium-Iron-Molybdenum), whereas Inconel 718 is a precipitation-hardenable (age-hardened) alloy.

Inconel 718 contains significant amounts of Niobium (Nb) and Titanium (Ti), which form gamma prime (γ′) and gamma double-prime (γ′′) precipitates. This makes it significantly harder and stronger than Hastelloy X at room and moderate temperatures. On the other hand, Hastelloy X focuses on oxidation resistance و fabricability, making it a “workhorse” for components that need to withstand extreme heat without necessarily carrying heavy structural loads.

| الممتلكات | Hastelloy X (UNS N06002) | إنكونيل 718 (UNS N07718) |

| Primary Strength Mechanism | Solid Solution | Precipitation Hardening |

| Density ($g/cm^3$) | 8.22 | 8.19 |

| Melting Range | 2300–2470°F (1260–1355°C) | 2300–2437°F (1260–1336°C) |

| Yield Strength (at 1200°F) | ~35,000 psi (240 MPa) | ~150,000 psi (1030 MPa) |

| Max Oxidation Limit | 2200°F (1200°C) | 1300°F (704°C) |

Hastelloy X vs 718 High Temperature Strength

When analyzing Hastelloy X vs 718 high temperature strength, you must distinguish between “load-bearing strength” and “environmental survival.”

-

إنكونيل 718 is the king of structural integrity up to 1300°F (700°C). It maintains incredible creep-rupture strength and tensile properties. However, once temperatures exceed this threshold, the precipitates that give 718 its strength begin to coarsen (overage), and the material loses its structural advantage rapidly.

-

هاستيلوي X does not have the same peak yield strength as 718, but it offers superior stability at much higher temperatures. It provides exceptional oxidation resistance up to 2200°F (1200°C). It resists carburization and nitriding, which are common failure modes in gas turbine combustion zones.

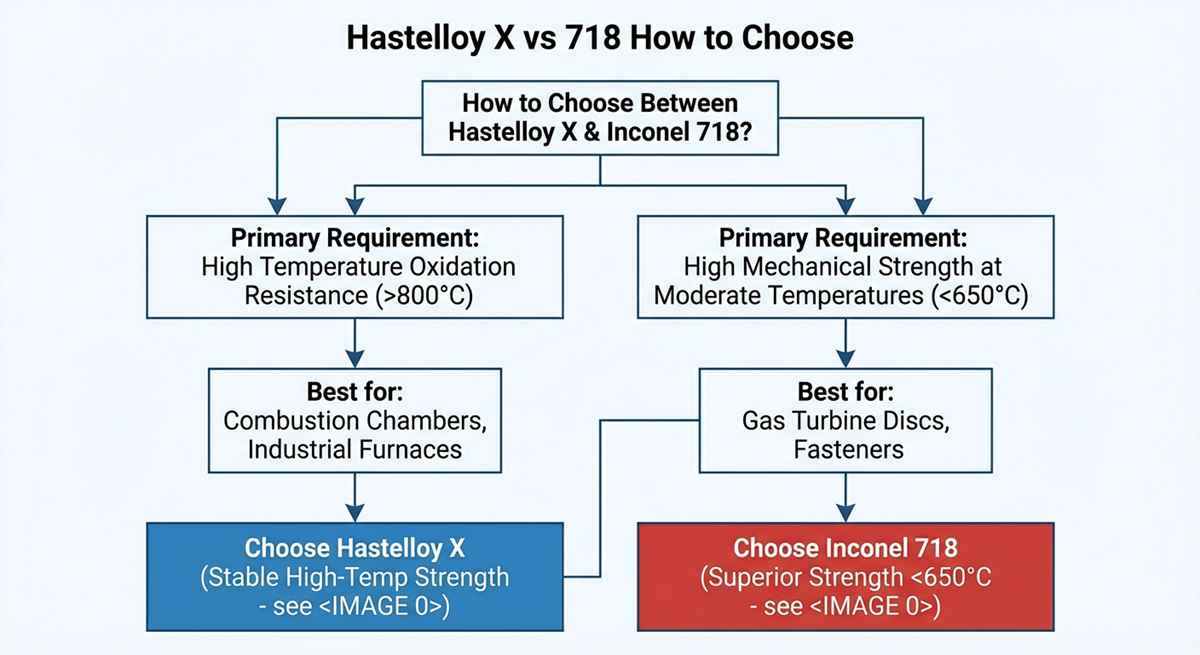

Hastelloy X vs 718 How to Choose

The decision on Hastelloy X vs 718 how to choose usually comes down to the operating temperature and the structural demand of the part.

-

Select Inconel 718 if: You are designing high-stress components like turbine disks, fasteners, or cryogenic tanks where yield strength and fatigue resistance are the top priorities below 1300°F.

-

Select Hastelloy X if: You are designing “hot-section” components like combustion liners, afterburners, or furnace retorts. If the part must survive in an oxidizing environment above 1500°F, Hastelloy X is the safer, more durable choice.

-

Fabrication Needs: Hastelloy X is generally easier to weld and form. Inconel 718, while weldable, is more susceptible to strain-age cracking and requires strict post-weld heat treatment (PWHT) to achieve its full strength.

أسئلة وأجوبة ذات صلة

Q1: Can Inconel 718 be used for furnace muffles? Generally, no. While 718 is strong, it is not optimized for the constant high-temperature oxidation found in furnaces. Hastelloy X or Inconel 600 are better suited for non-structural furnace environments.

Q2: Is Hastelloy X more expensive than Inconel 718? Prices fluctuate based on molybdenum and nickel markets, but Hastelloy X often carries a premium due to its specialized molybdenum content and lower production volume compared to the widely used Inconel 718.

Q3: Which alloy is better for cryogenic applications? Inconel 718 is exceptionally well-suited for cryogenic temperatures, as it maintains high toughness and strength without becoming brittle, making it a standard for liquid rocket propellant systems.