Incoloy 800H vs 800HT comparison

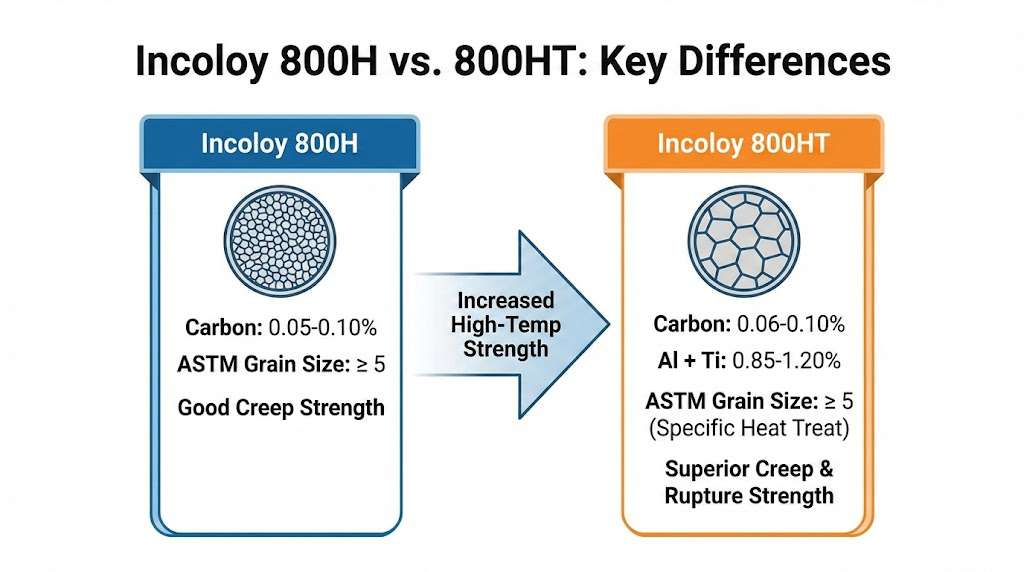

What they are (short): Incoloy 800H (UNS N08810) and Incoloy 800HT (UNS N08811) are controlled-chemistry, heat-treated versions of alloy 800 intended for elevated-temperature service. Both are derived from the base Incoloy 800 chemistry but are processed and limited to tighter compositional ranges (notably carbon, aluminium and titanium) and specific heat-treatment/grain-size requirements to improve long-term strength and creep behavior.

Key compositional and process differences

-

Carbon control: 800H targets a controlled carbon band (~0.05–0.10% C) to increase creep-strength over basic 800; 800HT has similarly restricted C (commonly specified ~0.06–0.10%) but paired with stricter Al+Ti limits. These small carbon windows materially affect carbide precipitation and creep life.

-

Aluminum + Titanium (Al+Ti): 800HT typically has a narrower, higher Al+Ti control (often specified as ~0.85–1.20% combined) compared with the broader limits allowed for 800H. That tighter control encourages stable microstructures and better high-temperature strength/oxidation resistance.

-

Heat treatment & grain size: 800H/800HT are frequently given a high-temperature anneal (e.g., ≥1149°C / ~2100°F) to produce a coarser, controlled grain size (ASTM 5 or coarser) which improves creep performance vs standard 800. 800HT is often specified to meet the strictest heat-treatment and grain-size controls.

Performance summary

-

Creep & rupture strength: Both 800H and 800HT show significantly higher creep and rupture strength than base alloy 800. 800HT generally exhibits the highest long-term creep strength, especially at the upper end of high-temperature service (above ~700°C), due to its tighter chemistry and heat-treat requirements.

-

Temperature window: Use 800H for reliable service in the 600–700°C range (and above where appropriate); when the design calls for the maximum possible long-term creep resistance or service above ~700°C for extended durations, 800HT is often the preferred grade.

Typical applications

-

800H: furnace components, petrochemical reformers, heat exchangers and other equipment where creep resistance above 600°C for many thousands of hours is required.

-

800HT: the same applications but where longer life at higher stress/temperature is required — tubes, springs, critical pressure parts and petrochemical crackers operating at more severe temperatures or where ASME/Code case stress-rupture limits require the tighter HT chemistry.

Incoloy 800H vs 800HT how to choose

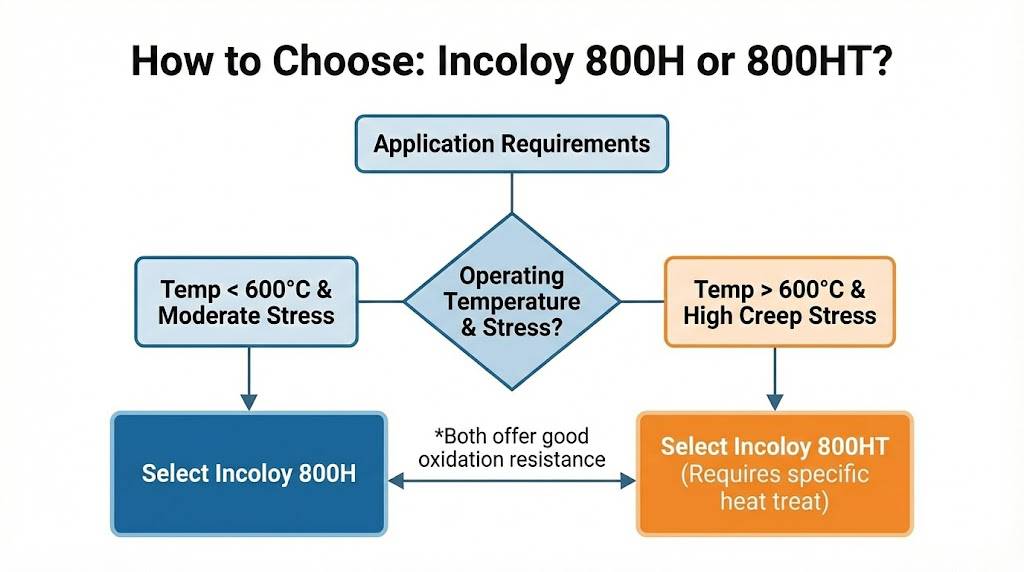

Selecting between Incoloy 800H vs 800HT is a matter of matching time-at-temperature, stress, oxide/carburizing environment, و code/certification requirements to the alloy’s microstructure and guaranteed properties.

Step-by-step selection checklist (practical)

-

Define design temperature and time horizon.

-

If the continuous service temperature is below ~600°C and life is moderate, base 800 could suffice; for continuous operation at or above ~600°C for long durations, start with 800H. For extended life above ~700°C or for very long design lives (tens of thousands to 100k+ hours), prioritize 800HT.

-

-

Estimate applied stress and environment.

-

High applied stress or environments that promote carburization/oxidation favor 800HT because its restricted Al+Ti and controlled heat-treatment yield better creep and oxidation resistance.

-

-

Check applicable codes and stress tables.

-

Many codes/ASME Code Cases publish allowable stresses for 800H and 800HT; when code compliance matters, select the grade listed or call out dual-certified material (800H/800HT) and reference the supplier’s certified data.

-

-

Consider manufacturing form and finishing.

-

If forming/welding is heavy, confirm post-weld heat treatment and whether the chosen alloy’s grain size/chemistry will be preserved by fabrication steps. 800HT’s tighter chemistry sometimes requires stricter control in fabrication.

-

-

Ask suppliers for creep-rupture curves and long-term data.

-

For any final choice, request supplier data (1000, 10k, 100k-hour stress-rupture or creep curves). This is the definitive input for design margins. Many mills publish normalized curves for 800H and 800HT.

-

Specification language to use in purchase orders / datasheets (examples)

-

Acceptable: “Material: Incoloy 800HT (UNS N08811) to ASTM/ASME [insert spec], heat-treated to 1149°C (2100°F) min.; chemical composition and grain-size to meet manufacturer’s 800HT limits; mill cert required showing Al+Ti and C ranges.”

-

Alternative (dual cert): “Material: Alloy 800H/800HT dual-certified; supplier to certify to both UNS N08810 and N08811 limits and provide creep-rupture data for intended service temperature.”

Using precise wording like this reduces ambiguity for procurement and supports SEO when published on product/spec pages.

800H vs 800HT creep resistance

Mechanisms that matter

-

Carbide precipitation and grain size: Controlled carbon content and heat treatment determine the distribution and type of carbides; these features control creep cavitation and grain-boundary weakness. 800HT’s tighter controls produce a microstructure that resists creep deformation longer under the same stress/temperature.

-

Al+Ti control & oxidation: Higher and controlled Al+Ti in the right balance promotes stable oxide scales and strengthens the matrix at high temperature (gamma prime formation is not strong in these alloys, but Al/Ti do influence precipitates and oxidation resistance), which helps long-term creep life and resistance to embrittlement.

What the data says (how to interpret mill charts)

-

Supplier graphs show creep rupture strength curves for 800H and 800HT plotted as stress vs log(time) at fixed temperatures. Typical observations: at a given stress and temperature, 800HT reaches a target rupture time at a higher stress than 800H — i.e., 800HT lasts longer or carries more stress for the same life. Ask suppliers for curves at your design temperatures (600°C, 700°C, 760°C etc.).

Design rule of thumb

-

If your component must survive very long exposures (>10,000–100,000 hours) at ≥700°C or you require the highest allowable stress values from ASME tables, choose 800HT. For robust service above ~600°C where 800H’s creep tables already meet allowable stress and cost sensitivity matters, 800H is often the pragmatic choice. Always validate with supplier creep-rupture data for the actual stress and temperature.

Incoloy 800H vs 800HT Difference Quick Check Table

| Property / Feature | Incoloy 800H (UNS N08810) | Incoloy 800HT (UNS N08811) | Practical note |

|---|---|---|---|

| Carbon (typical spec) | ~0.05 – 0.10% | ~0.06 – 0.10% (tighter control) | Both higher than base 800; HT often slightly tighter. |

| Al + Ti (combined) | Wider range (broader limits) | Narrower, more restrictive (e.g. 0.85–1.20% combined) | HT’s restricted Al+Ti improves high-T strength/oxidation. |

| Heat treatment | High-temp anneal customary | High-temp anneal required; stricter min temp | HT often called out with specific anneal temperature. |

| Grain size control | Controlled (coarser than base 800) | Controlled; often specified ASTM 5 or coarser | Grain control helps creep life. |

| Creep resistance | High (vs 800) | Higher (best of the 3) | Choose HT for max long-term creep life. |

| Typical use temp focus | ~600–700°C service | ≥700°C service and longest lives | Match to time-at-temp and stress. |

أسئلة وأجوبة ذات صلة

Q1 — Can I substitute 800H for 800HT to save cost?

A: Substitution is possible in some cases but not universally safe. If the application’s allowable stress is derived from 800HT tables or the design life/temperature demands HT’s tighter chemistry, substitution can reduce life or violate code limits. Always check ASME/code allowable stresses and supplier creep data before substituting.

Q2 — What temperatures are considered “safe” for continuous service for 800H and 800HT?

A: There’s no single cutoff—designers use creep/rupture data and code allowable stresses. In practice, 800H is commonly specified for reliable long-term service at and above 600°C; 800HT is chosen when the design calls for reliable, long life at or above ~700°C or when the highest allowable stresses are required. Confirm with mill-published stress tables.

Q3 — Do 800H and 800HT weld similarly, and does welding affect creep life?

A: Both weldable with standard Ni-Cr procedures, but welding can locally alter chemistry and microstructure; post-weld heat treatment and fabrication controls should be specified if creep life is critical. HT’s tighter chemistry means fabricator controls (filler metal, heat input, PWHT) should be verified to avoid degraded creep properties in the weld or HAZ.