In the realm of high-purity nickel alloys, Nickel 200 (UNS N02200) and Nickel 201 (UNS N02201) stand as the workhorses of the chemical processing and aerospace industries. While both alloys offer exceptional resistance to caustic alkalis and distilled water, understanding the subtle chemical nuances between them is critical for ensuring structural integrity in high-temperature environments.

Nickel 200 vs 201 differences

The fundamental difference between Nickel 200 and Nickel 201 lies in their carbon content. Nickel 200 is a commercially pure wrought nickel with a maximum carbon content of 0.15%. In contrast, Nickel 201 is the “low-carbon” version, restricted to a maximum of 0.02%.

This discrepancy in carbon drastically alters their thermal stability. When Nickel 200 is exposed to temperatures exceeding 315°C (600°F) for prolonged periods, the excess carbon precipitates as graphite at the grain boundaries. This phenomenon, known as graphitization, leads to a severe loss of ductility and eventual intergranular embrittlement. Nickel 201, with its controlled low carbon, is specifically designed to bypass this risk, maintaining its mechanical properties up to 650°C (1200°F).

| الممتلكات | Nickel 200 (UNS N02200) | Nickel 201 (UNS N02201) |

| Carbon Content (Max) | 0.15% | 0.02% |

| الكثافة | 8.89 g/cm³ | 8.89 g/cm³ |

| درجة الحرارة القصوى للخدمة | 315°C (600°F) | 650 درجة مئوية (1200 درجة فهرنهايت) |

| Tensile Strength (Annealed) | 67,000 psi (462 MPa) | 58,000 psi (400 MPa) |

| Yield Strength (Annealed) | 21,500 psi (148 MPa) | 15,000 psi (103 MPa) |

| الصلابة (روكويل ب) | 45 – 55 | 40 – 50 |

Nickel 200 vs 201 how to choose

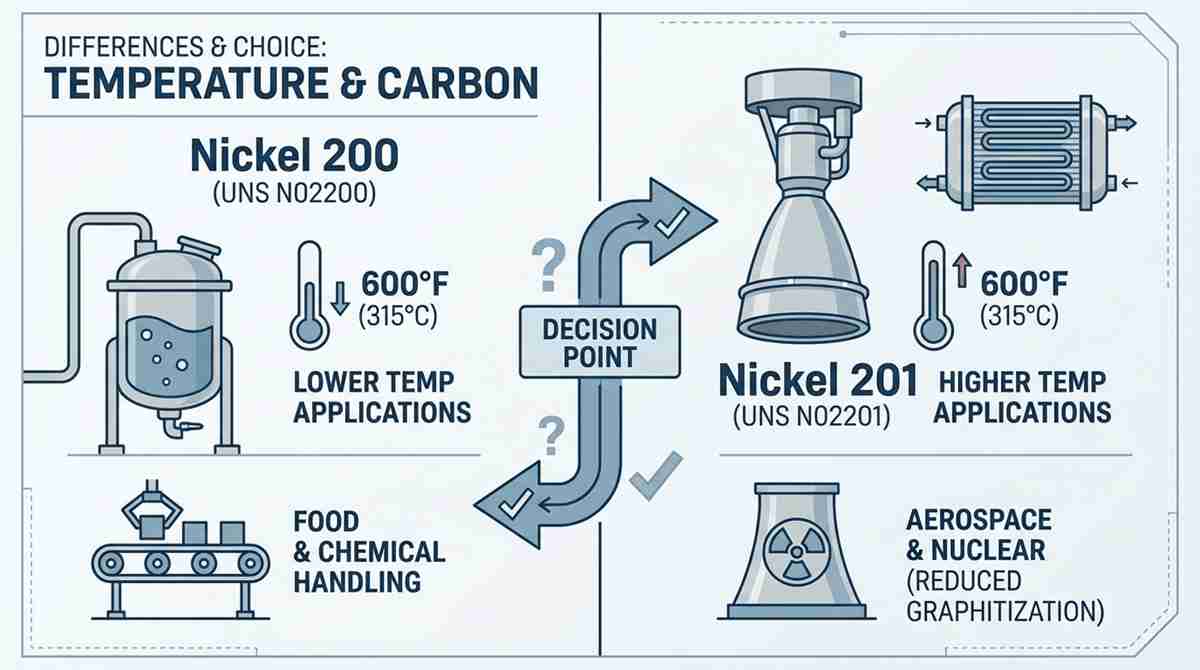

Selecting between these two grades is primarily dictated by the operating temperature and the required mechanical strength.

-

Temperature Threshold: If your application involves continuous service above 315°C (600°F), Nickel 201 is the only viable choice. It is frequently used in caustic evaporators, combustion boats, and electronic components where high heat is a factor.

-

Mechanical Strength: Because carbon acts as a strengthening agent in the nickel matrix, Nickel 200 exhibits slightly higher hardness and tensile strength than Nickel 201. For ambient temperature applications or those below the 315°C limit, Nickel 200 provides better structural rigidity.

-

Corrosion Resistance: Both grades offer identical resistance in most environments, particularly against caustic soda (NaOH) and potassium hydroxide. However, for pressurized vessel construction, ensure the material meets ASME Boiler and Pressure Vessel Code requirements specific to the intended temperature.

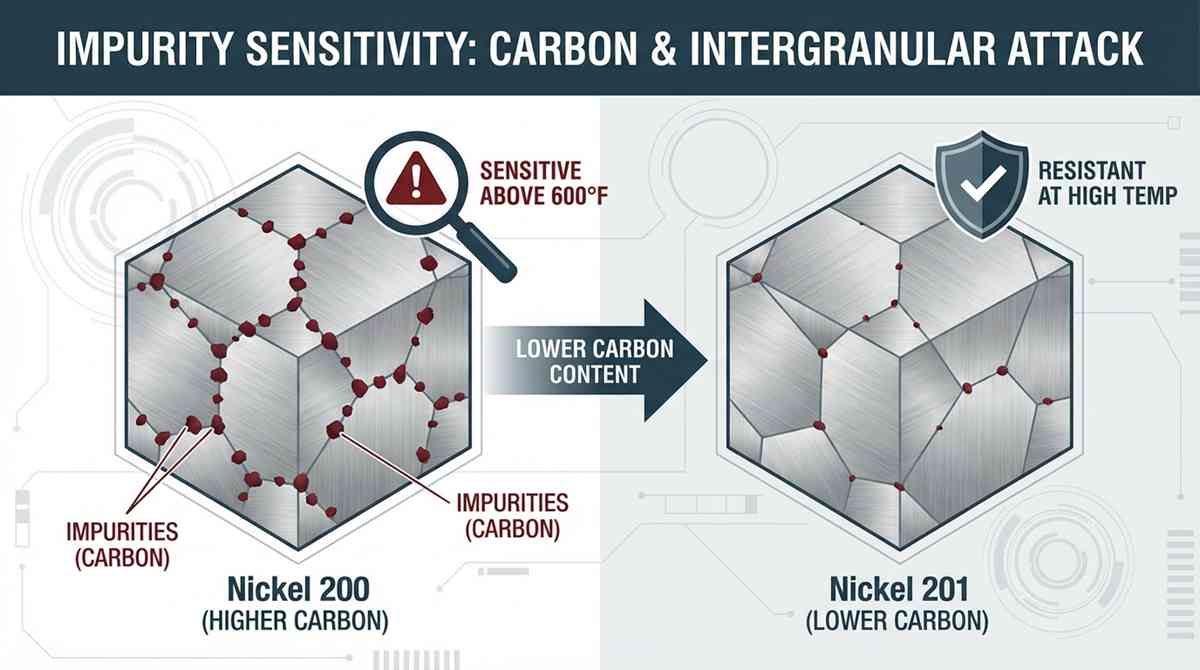

Nickel 200 vs 201 impurity sensitivity

Beyond carbon, both alloys are highly sensitive to sulfur contamination. Exposure to sulfur-bearing compounds at elevated temperatures can cause “sulfur embrittlement.” Sulfur migrates to the grain boundaries, forming a low-melting-point nickel sulfide eutectic that destroys the metal’s ductility.

Furthermore, Nickel 200’s sensitivity to carbon precipitation is its “Achilles’ heel” in high-temp scenarios. While Nickel 201 mitigates this, users must still ensure that fabrication processes (like welding or heat treatment) do not introduce exogenous carbon or sulfur. Proper surface cleaning and the use of low-carbon filler metals are essential to maintaining the purity and performance of these alloys.

أسئلة وأجوبة ذات صلة

Q1: Can Nickel 200 and Nickel 201 be dual-certified? Yes. A material can be dual-certified if its carbon content is ≤ 0.02% (meeting Nickel 201 specs) while still meeting the mechanical strength requirements of Nickel 200.

Q2: Which alloy is better for caustic soda processing? Both are excellent. However, if the process involves heating caustic soda to high concentrations at temperatures above 315°C, Nickel 201 must be used to prevent stress corrosion cracking and graphitization.

Q3: Is there a significant price difference between the two? Generally, the price difference is minimal. The cost is driven more by the prevailing market price of raw nickel than by the carbon refinement process.