However, unlike simpler metals, the precise “balance” of nickel in Alloy 625 fluctuates based on the inclusion of other hardening elements like Molybdenum and Niobium. This guide breaks down the exact composition standards, why that specific percentage matters, and how the nickel content defines the material’s performance.

The Exact Chemical Breakdown: What the Standards Say

To understand exactly how much nickel is in Inconel 625, we must look at the governing industry standards, specifically ASTM B443 et AMS 5599. These specifications dictate the boundaries for chemical composition to ensure the material performs predictable under high stress.

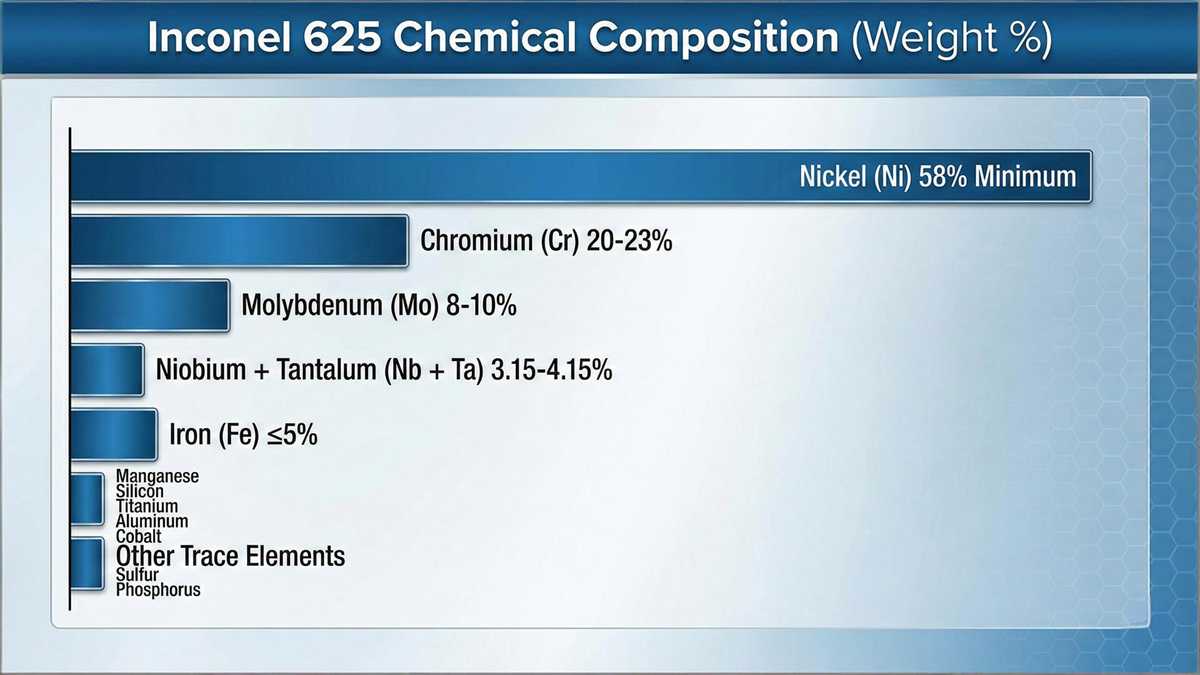

While Nickel is the primary element, it serves as the base for a complex matrix. Here is the standard limiting chemical composition (by weight %):

| Élément | Symbol | Percentage (%) |

| Nickel | Ni | 58.0 min (équilibre) |

| Chrome | Cr | 20.0 – 23.0 |

| Molybdène | Mo | 8.0 – 10.0 |

| Niobium + Tantalum | Nb + Ta | 3.15 – 4.15 |

| Iron | Fe | 5.0 max |

| Manganese | Mn | 0,50 max |

| Silicon | Si | 0,50 max |

Note: In many material certifications (MTRs), you will see the Nickel content listed as “Balance.” This means after all other specific elements (Cr, Mo, Nb, Fe) are accounted for, Nickel makes up the remainder. In practice, this usually results in a Nickel content ranging between 60% and 62%.

Why the “58% Minimum” Threshold Matters

The question of how much nickel is in Inconel 625 isn’t just about categorization; it is about survival in hostile environments. The specific threshold of 58% is critical for three main reasons:

1. Immunity to Chloride-Ion Stress-Corrosion Cracking

The most significant benefit of having over 58% nickel is virtually total immunity to chloride-ion stress-corrosion cracking (SCC). Stainless steels with lower nickel contents (like 316SS) frequently fail in saltwater or chemical processing environments because they crack under tensile stress. The high nickel content in Inconel 625 acts as a stabilizer, preventing this specific failure mode.

2. High-Temperature Stability

Nickel is an austenitic stabilizer. By maintaining a high nickel base, Inconel 625 retains its face-centered cubic (FCC) crystal structure from cryogenic temperatures up to 1800°F (982°C). This ensures that the material does not become brittle at freezing temperatures or lose its structural integrity in jet engine exhaust systems.

3. Solubility for Alloying Elements

Nickel has a unique ability to hold large amounts of other elements in solid solution. The matrix formed by the ~60% nickel content allows for the addition of Molybdenum (8-10%) and Niobium (3-4%). It is the interaction between the Nickel base and these stiffening elements that gives 625 its incredible yield strength without requiring precipitation hardening heat treatments.

Inconel 625 vs. Other Alloys: The Nickel Difference

To fully appreciate the composition, it helps to compare how much nickel is in Inconel 625 versus other common superalloys.

-

Inconel 625 (58% min Ni): Designed for maximum corrosion resistance and solid-solution strengthening.

-

Inconel 718 (~50-55% Ni): Contains less nickel and more Iron (roughly 17-20%). While 718 is stronger due to age-hardening, 625 offers superior corrosion resistance because of the higher nickel and molybdenum content.

-

Hastelloy C-276 (~57% Ni): Very similar nickel content to 625, but with higher Molybdenum and lower Chromium.

When specifying materials for seawater, aerospace, or chemical processing, verifying how much nickel is in Inconel 625 is the first step in ensuring quality. With a minimum of 58.0% Nickel combined with high Chromium and Molybdenum, this superalloy offers a rare balance of fabricability and extreme resistance to environmental attack.

Foire aux questions (FAQ)

Q1: Does the Nickel content in Inconel 625 make it magnetic?No. Due to the high Nickel content (minimum 58%) and its austenitic crystal structure, Inconel 625 is non-magnetic. It remains non-magnetic even after extended exposure to very low or very high temperatures, which makes it useful in sensitive electronic or submarine applications.

Q2: How does the Nickel content in Inconel 625 compare to Inconel 718?Inconel 625 generally has a higher Nickel content (58% minimum) compared to Inconel 718, which typically contains between 50% and 55% Nickel. Inconel 718 balances this with a higher Iron content. The higher nickel in 625 contributes to its superior oxidation and corrosion resistance compared to 718.

Q3: Is high Nickel content the only reason Inconel 625 is corrosion-resistant?While the high Nickel content provides immunity to stress-corrosion cracking, it is not the only factor. The corrosion resistance of Inconel 625 is a result of the synergy between Nickel, Chromium (oxidizing resistance), and Molybdenum (pitting resistance). The Nickel matrix essentially holds these elements together to provide comprehensive protection.