Alliage 330

Alloy 330 is an austenitic nickel-iron-chromium alloy with a specific addition of 1.25% silicon. It was developed specifically to handle the rigors of the industrial heat-treating environment, offering exceptional resistance to carburization and thermal shock.

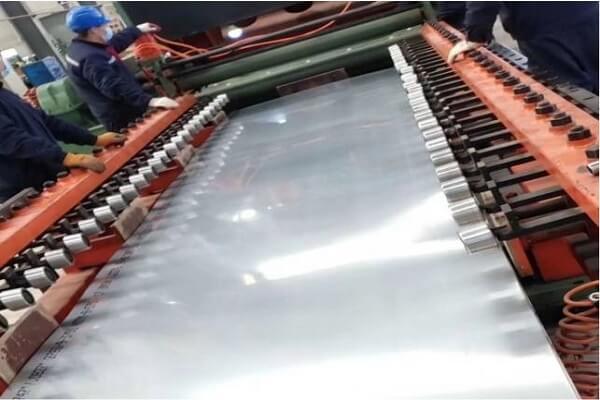

- Formes courantes : Plate, Sheet, Round Bar, Pipe, Mesh.

- Caractéristiques principales : Excellent Carburization & Oxidation Resistance.

- La force : Good strength up to 2100°F (1150°C).

- Stability: Resistant to thermal cycling and quenching.

In heat treating furnaces, metals undergo brutal conditions: rapid heating, quenching, and exposure to carbon-rich atmospheres. Standard stainless steels become brittle or dissolve. Alloy 330 excels here because its **Silicon** content aids in the formation of a tightly adherent oxide scale, while its high **Nickel** content (35%) prevents embrittlement (sigma phase formation) and stress corrosion cracking.

Résistance à la cémentation

The alloy resists the absorption of carbon and nitrogen, preventing the material from becoming brittle during carburizing and carbonitriding cycles.

Thermal Shock Resistance

Designed to withstand rapid temperature changes, such as oil quenching, without cracking or severe distortion.

Immunity to Sigma Phase

The microstructure remains stable even after long-term exposure to intermediate temperatures, unlike Incoloy 800 or 300 series stainless.

| Élément | Contenu (%) |

|---|---|

| Nickel (Ni) | 34.0 - 37.0 |

| Chrome (Cr) | 17.0 - 20.0 |

| Silicium (Si) | 1.0 - 1.5 |

| Fer (Fe) | Équilibre |

| Manganèse (Mn) | 2.0 max |

| Carbone (C) | 0.08 max |

*Note: The Silicon addition is the critical differentiator from Incoloy 800.

| Forme du produit | Normes ASTM / ASME |

|---|---|

| Plaque, feuille, bande | ASTM B536, ASME SB536 |

| Bar & Rod | ASTM B511, ASME SB511 |

| Tubes (sans soudure et soudés) | ASTM B535, ASTM B710, ASME SB535 |

| Pipe Fittings | ASTM B366, ASME SB366 |

| Propriété | Valeurs typiques (température ambiante) |

|---|---|

| Résistance à la traction | 80 - 95 ksi (550 - 655 MPa) |

| Limite d'élasticité (décalage de 0,2%) | 30 - 45 ksi (205 - 310 MPa) |

| Élongation | 35 - 45 % |

| Dureté (Rockwell B) | 70 - 85 HRB |

*Note: Alloy 330 remains ductile even after long-term service.

Heat Treating Baskets

Trays, baskets, and fixtures used to hold parts during carburizing and hardening cycles.

Furnace Muffles

Retorts and muffles that must contain controlled atmospheres at high temperatures.

Radiant Tubes

Heating tubes in gas-fired furnaces that are subjected to intense thermal cycling.

Petrochemical

Pigtails and headers in pyrolysis furnaces requiring carburization resistance.

Need Alloy 330 for Furnaces?

We maintain a large stock of Alloy 330 plate, bar, and pipe. Contact us for cut-to-size material for your thermal processing equipment.

Obtenir un devis rapide