In the world of high-performance nickel-chromium-molybdenum alloys, two names dominate the conversation: Hastelloy C276 and Hastelloy C22. For engineers and procurement specialists in the chemical processing industry, distinguishing between these two “C-type” alloys is critical. While they share a lineage, their distinct chemical compositions dictate how they behave under severe corrosive stress.

This guide breaks down the technical nuances, helping you optimize material selection for longevity and safety.

C276 vs C22 differences

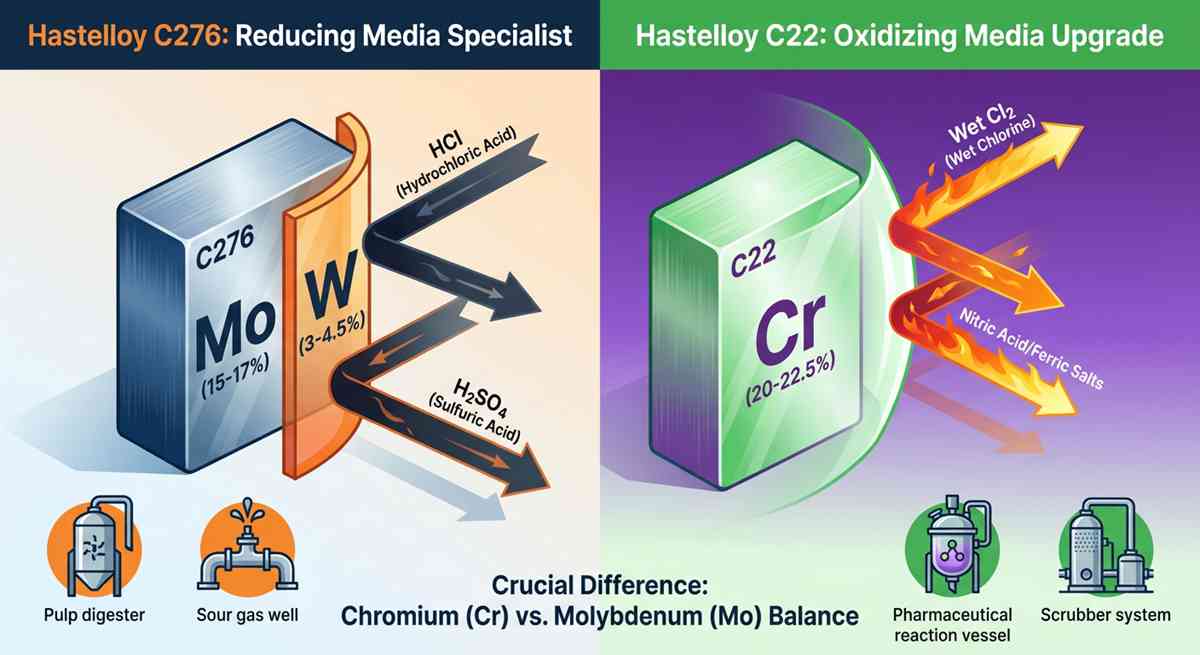

The fundamental C276 vs C22 differences lie in their elemental “recipes.” While both are Ni-Cr-Mo superalloys designed to resist aggressive corrosion, the balance of Chromium (Cr) and Molybdenum (Mo) sets them apart.

Hastelloy C276 (UNS N10276) is considered the “workhorse” of the industry. It relies on a high Molybdenum content (15-17%) and Tungsten (3-4.5%) to provide exceptional resistance to reducing environments (like hydrochloric acid). However, its Chromium content is lower (approx. 14.5-16.5%).

Hastelloy C22 (UNS N06022), often viewed as the upgrade, adjusts this balance. It increases Chromium to approximately 20-22.5% while slightly lowering Molybdenum (12.5-14.5%).

Why does this matter?

-

Oxidizing Resistance: The higher Chromium in C22 gives it vastly superior resistance to oxidizing media (such as wet chlorine, nitric acid mixtures, or ferric salts) compared to C276.

-

Weldability: Both possess excellent weldability, but C22 has better resistance to grain boundary precipitation in the weld heat-affected zone (HAZ), making it slightly more robust in as-welded conditions for multiprocess plants.

To quantify this, we look at the Pitting Resistance Equivalent Number (PREN).

Generally, C22 exhibits a higher PREN, indicating better resistance to localized pitting and crevice corrosion in stagnant high-chloride environments.

C276 vs C22 chemical processing applications

When mapping out C276 vs C22 chemical processing applications, the decision usually hinges on the specific acid stream and the presence of oxidizers.

Hastelloy C276 is the standard for:

-

Pure Reducing Acids: It performs exceptionally well in hydrochloric and sulfuric acid environments where no oxidizing agents are present.

-

Pulp and Paper: Digesters and bleach plants often utilize C276.

-

Sour Gas Wells: Downhole environments rich in H2S (Hydrogen Sulfide) and CO2.

Hastelloy C22 is the preferred choice for:

-

Pharmaceutical Manufacturing: Because C22 is less likely to corrode and contaminate sensitive batches, it is the standard for API (Active Pharmaceutical Ingredient) reaction vessels.

-

Agrochemicals & Pesticides: Production lines that switch between oxidizing and reducing steps (“swing” processes) require the versatility of C22.

-

Scrubbers & Desulfurization: In Flue Gas Desulfurization (FGD) systems where scrubber liquids can become highly acidic and oxidizing due to fly ash, C22 outperforms C276.

C276 vs C22 how to choose

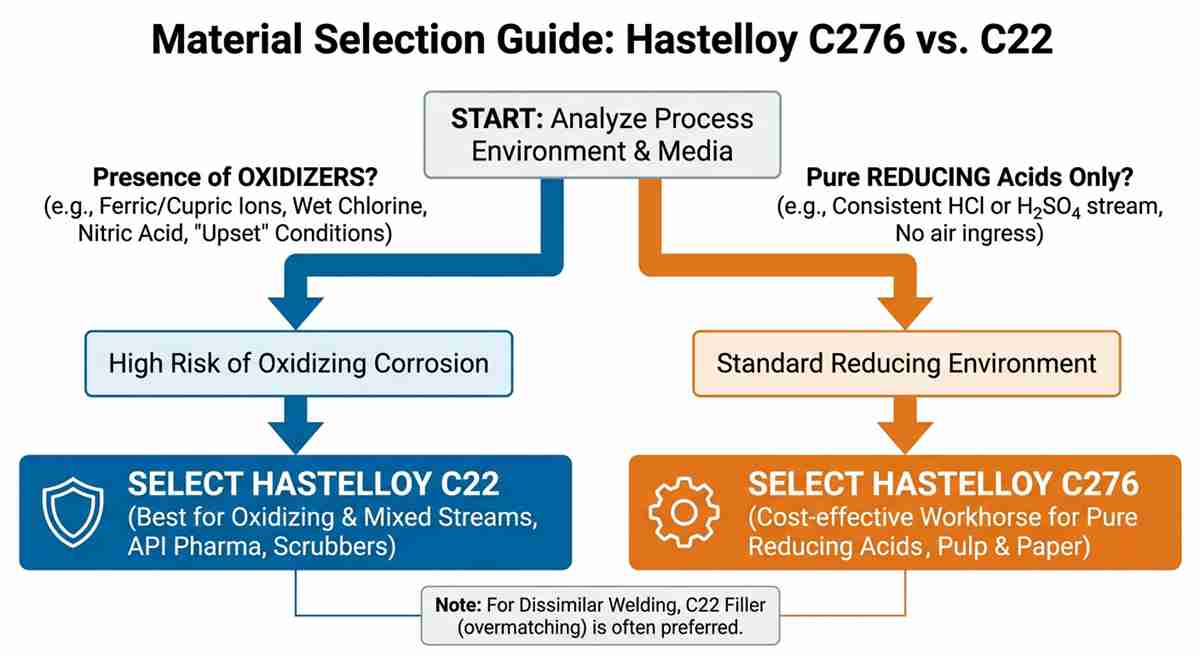

Determining C276 vs C22 how to choose requires a specific analysis of your process media. It is not always about buying the “better” alloy, but the “right” one.

-

Analyze the Oxidizers: If your stream contains ferric ions (Fe3+), cupric ions (Cu2+), free chlorine, or nitric acid, choose C22. C276 may suffer from premature failure in these conditions due to its lower chromium content.

-

Evaluate “Upset” Conditions: If your plant runs a consistent reducing acid stream, C276 is sufficient and cost-effective. However, if your process is prone to “upsets” (accidental air ingress or temperature spikes creating oxidizing conditions), C22 acts as an insurance policy.

-

Cost and Availability: Historically, C276 was significantly cheaper. Today, the price gap has narrowed, but C276 remains more widely available in stock (sheets, bars, flanges). If you need a quick repair for a standard reducing line, C276 is often the logistical winner.

Domande e risposte correlate

Q1: Can I weld Hastelloy C22 to C276?

A: Yes, dissimilar welding is common. You should generally use the welding filler metal with the higher alloy content (overmatching). In this case, use C22 filler metal (ERNiCrMo-10) to ensure the weld bead has corrosion resistance equal to or better than the C276 base metal.

Q2: Is Hastelloy C22 always better than C276?

A: No. In purely reducing hydrochloric acid environments at specific concentrations and temperatures, the higher Molybdenum content in C276 can actually offer slightly better corrosion rates than C22. C22 is “better” specifically for mixed or oxidizing streams.

Q3: How do I distinguish them visually?

A: You cannot distinguish them by the naked eye; both are bright, silver-grey metals. You must use Positive Material Identification (PMI) equipment (XRF handheld analyzer) to check the Chromium/Molybdenum ratio or look for the heat number and mill test report (MTR).