Invar® / Controlled Expansion Alloys

A specialized family of Nickel-Iron alloys engineered to have an exceptionally low or controlled coefficient of thermal expansion (CTE). Essential for precision applications where dimensional stability is critical.

Invar 36

A 36% nickel-iron alloy with the lowest coefficient of thermal expansion of any commercially available metal (approx. 1/10th that of carbon steel) from cryogenic temperatures up to 400°F.

Invar 42

A 42% nickel-iron alloy designed with a constant rate of thermal expansion that matches silicon chips, glass, and alumina ceramics. Critical for electronic packaging and hermetic sealing.

Why Controlled Expansion Matters?

Most metals expand significantly when heated. In precision instruments, this expansion causes misalignment. In electronics, the mismatch between a metal chip frame and the silicon chip causes cracking.

Invar Alloys solve this. Invar 36 essentially does not expand at all near room temperature. Invar 42 expands at a specific, controlled rate to move exactly in sync with electronic components.

| Grado di lega | Nickel Content | Expansion Characteristic | Applicazione primaria |

|---|---|---|---|

| Invar 36 | 36% | Near Zero expansion up to 400°F (200°C). | Composite molds, laser positioning, LNG piping. |

| Invar 42 | 42% | Controlled expansion to match Silicon/Ceramic. | Lead frames, hermetic glass-to-metal seals. |

Elettronica

Integrated circuit lead frames and semiconductor packaging.

Aerospace Composites

Lay-up molds for carbon fiber parts (Invar 36 matches carbon fiber CTE).

Cryogenics & LNG

Piping for Liquefied Natural Gas (-162°C) requiring stability.

Need Precision Alloy Material?

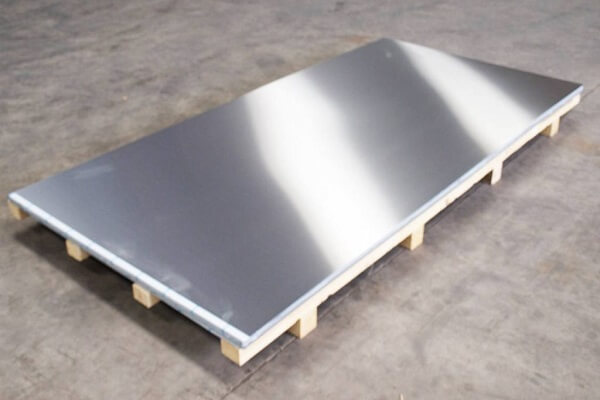

We stock Invar 36 and 42 in plate, sheet, and round bar. Cut-to-size services available for tooling plate.

Richiesta di preventivo