Choosing the right nickel-based superalloy is critical for aerospace, power generation, and chemical processing. Two of the most prominent contenders are ハステロイX そして インコネル718. While both offer exceptional performance, they serve very different mechanical and thermal roles.

Hastelloy X vs 718 Comparison

At the molecular level, the fundamental difference between ハステロイX そして インコネル718 lies in their strengthening mechanisms. Hastelloy X is a 固溶体強化 alloy (predominantly Nickel-Chromium-Iron-Molybdenum), whereas Inconel 718 is a precipitation-hardenable (age-hardened) alloy.

Inconel 718 contains significant amounts of Niobium (Nb) and Titanium (Ti), which form gamma prime (γ′) and gamma double-prime (γ′′) precipitates. This makes it significantly harder and stronger than Hastelloy X at room and moderate temperatures. On the other hand, Hastelloy X focuses on oxidation resistance そして fabricability, making it a “workhorse” for components that need to withstand extreme heat without necessarily carrying heavy structural loads.

| プロパティ | Hastelloy X (UNS N06002) | インコネル718(UNS N07718) |

| Primary Strength Mechanism | Solid Solution | Precipitation Hardening |

| Density ($g/cm^3$) | 8.22 | 8.19 |

| Melting Range | 2300–2470°F (1260–1355°C) | 2300–2437°F (1260–1336°C) |

| Yield Strength (at 1200°F) | ~35,000 psi (240 MPa) | ~150,000 psi (1030 MPa) |

| Max Oxidation Limit | 2200°F (1200°C) | 1300°F (704°C) |

Hastelloy X vs 718 High Temperature Strength

When analyzing Hastelloy X vs 718 high temperature strength, you must distinguish between “load-bearing strength” and “environmental survival.”

-

インコネル718 is the king of structural integrity up to 1300°F (700°C). It maintains incredible creep-rupture strength and tensile properties. However, once temperatures exceed this threshold, the precipitates that give 718 its strength begin to coarsen (overage), and the material loses its structural advantage rapidly.

-

ハステロイX does not have the same peak yield strength as 718, but it offers superior stability at much higher temperatures. It provides exceptional oxidation resistance up to 2200°F (1200°C). It resists carburization and nitriding, which are common failure modes in gas turbine combustion zones.

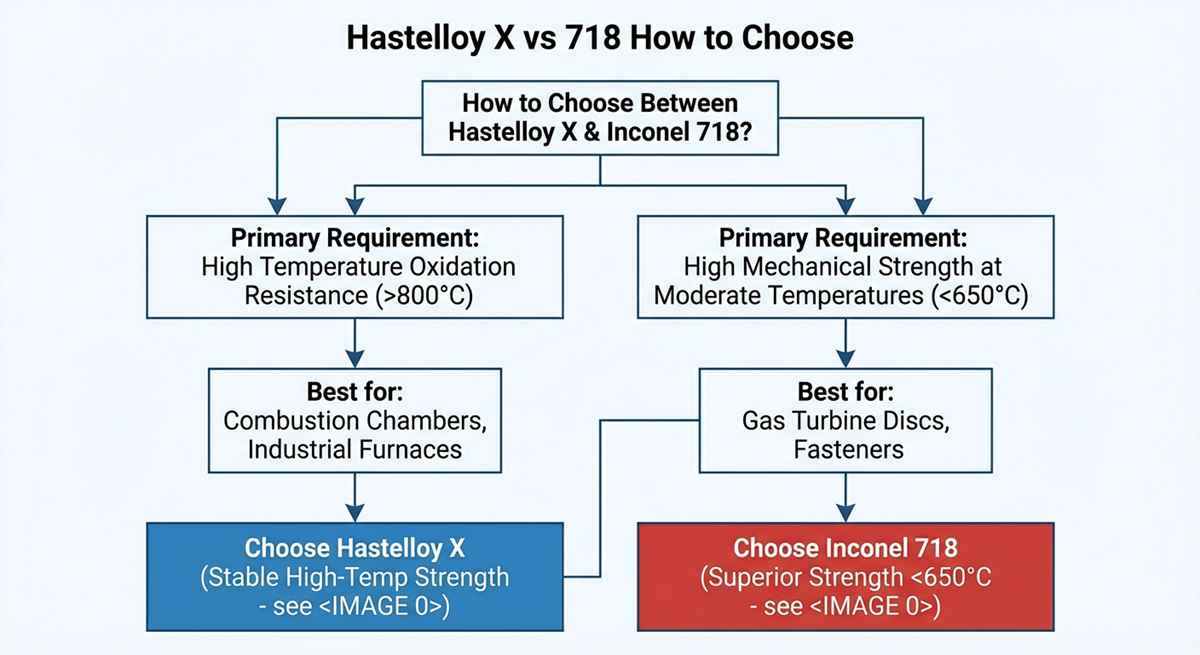

Hastelloy X vs 718 How to Choose

The decision on Hastelloy X vs 718 how to choose usually comes down to the operating temperature and the structural demand of the part.

-

Select Inconel 718 if: You are designing high-stress components like turbine disks, fasteners, or cryogenic tanks where yield strength and fatigue resistance are the top priorities below 1300°F.

-

Select Hastelloy X if: You are designing “hot-section” components like combustion liners, afterburners, or furnace retorts. If the part must survive in an oxidizing environment above 1500°F, Hastelloy X is the safer, more durable choice.

-

Fabrication Needs: Hastelloy X is generally easier to weld and form. Inconel 718, while weldable, is more susceptible to strain-age cracking and requires strict post-weld heat treatment (PWHT) to achieve its full strength.

関連Q&A

Q1: Can Inconel 718 be used for furnace muffles? Generally, no. While 718 is strong, it is not optimized for the constant high-temperature oxidation found in furnaces. Hastelloy X or Inconel 600 are better suited for non-structural furnace environments.

Q2: Is Hastelloy X more expensive than Inconel 718? Prices fluctuate based on molybdenum and nickel markets, but Hastelloy X often carries a premium due to its specialized molybdenum content and lower production volume compared to the widely used Inconel 718.

Q3: Which alloy is better for cryogenic applications? Inconel 718 is exceptionally well-suited for cryogenic temperatures, as it maintains high toughness and strength without becoming brittle, making it a standard for liquid rocket propellant systems.