In the realm of extreme metallurgy, 인코넬 625 그리고 인코넬 718 stand as the industry standards for nickel-based superalloys. While they share a base composition of nickel and chromium, their distinct microstructural strengthening mechanisms dictate vastly different applications.

For engineers and metallurgists, the choice between these two grades is rarely about “better” or “worse”—it is about optimizing for corrosion resistance (625) versus mechanical strength (718). This guide analyzes the critical distinctions in metallurgy, thermal stability, and machinability.

Inconel 625 vs 718 Comparison

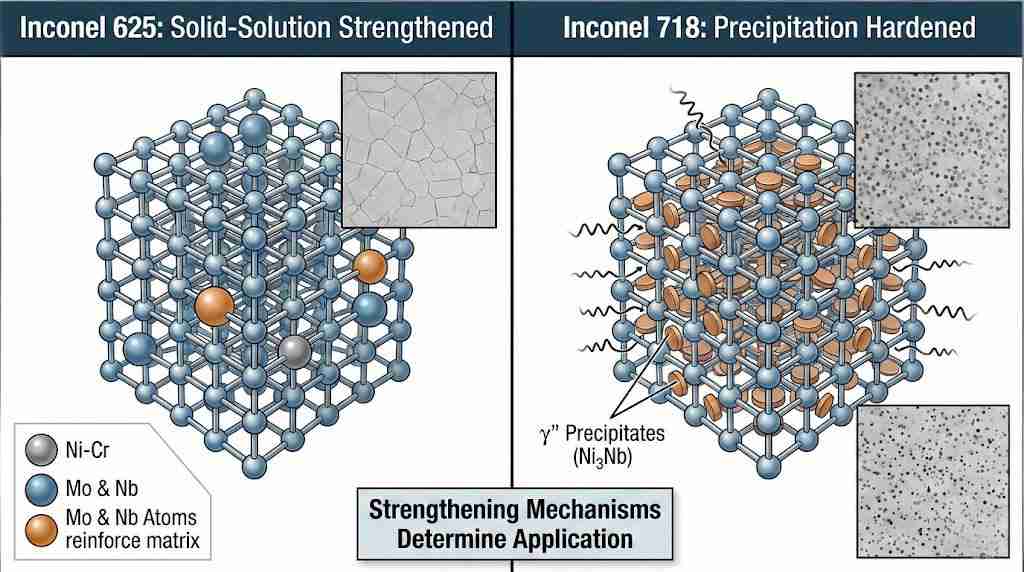

The fundamental difference lies in how these alloys achieve their strength.

-

인코넬 625(UNS N06625) is primarily a solid-solution strengthened alloy. It derives its strength from the stiffening effect of Molybdenum (Mo) and Niobium (Nb) in the nickel-chromium matrix. It does not require age-hardening heat treatments to achieve its properties, retaining excellent ductility and weldability.

-

Inconel 718 (UNS N07718) 는 precipitation-hardened (age-hardened) alloy. The addition of Titanium (Ti) and Aluminum (Al), alongside Niobium, allows for the formation of Gamma Double Prime (γ′′) precipitates (Ni3Nb) during heat treatment. This microstructure delivers exceptionally high yield strength.

Chemical Composition Differences

| 요소 | Inconel 625 (Weight %) | Inconel 718 (Weight %) | 성능에 미치는 영향 |

| 니켈(Ni) | ~58% (Min) | ~50 – 55% | 625 has higher Ni for better corrosion resistance. |

| 크롬(Cr) | 20 – 23% | 17 – 21% | Both offer excellent oxidation resistance. |

| 몰리브덴(Mo) | 8 – 10% | 2.8 – 3.3% | Key Difference: High Mo in 625 grants superior pitting resistance. |

| Niobium (Nb) | 3.15 – 4.15% | 4.75 – 5.5% | Higher Nb in 718 drives the precipitation hardening response. |

| Titanium/Aluminum | < 0.4% | Ti: 0.65-1.15% / Al: 0.2-0.8% | Essential for 718’s age-hardening process. |

Mechanical Properties (Typical Room Temperature)

| 속성 | Inconel 625 (Annealed) | Inconel 718 (Solution + Aged) |

| 항복 강도(0.2% 오프셋) | 414 – 650 MPa | 1034 – 1100 MPa |

| 인장 강도 | 827 – 1000 MPa | 1240 – 1350 MPa |

| Hardness (Rockwell) | 145 – 220 HB | 331 – 444 HB (36-44 HRC) |

| 신장 | 30 – 60% (High Ductility) | 12 – 21% |

Verdict: If your application demands structural rigidity under extreme load, Inconel 718 provides nearly double the yield strength of 625.

Inconel 625 vs 718 High Temperature Performance

Defining “high temperature” is critical when choosing between these alloys, as their performance curves diverge significantly past 650°C (1200°F).

1. Creep Rupture and Strength Stability

Inconel 718 is the dominant choice for high-stress applications up to 700°C (1300°F). Within this range, the γ′′ precipitates effectively block dislocation movement, preventing creep. However, above 700°C, these precipitates become unstable and coarsen, causing a rapid drop in mechanical strength.

2. Oxidation and Thermal Stability

Inconel 625 exhibits superior stability at ultra-high temperatures (up to 982°C / 1800°F). Because it relies on solid-solution strengthening rather than precipitates, it does not suffer from the same coarsening issues as 718. For unloaded or low-stress components exposed to extreme heat (like exhaust ducts or flare stacks), 625 is the safer option.

3. Cryogenic Performance

Both alloys are excellent for cryogenics, but Inconel 718 is often preferred for cryogenic bolts and fasteners because it retains its high tensile strength without becoming brittle at temperatures near absolute zero.

Inconel 625 vs 718 How to Choose

To streamline the procurement decision, evaluate the following three constraints:

Scenario A: Extreme Corrosion (Marine & Chemical)

Choose Inconel 625. The high Molybdenum content (9%) gives 625 a Pitting Resistance Equivalent Number (PREN) significantly higher than 718. It is virtually immune to chloride-ion stress-corrosion cracking.

-

Typical Applications: Subsea piping, heat exchangers in acid processing, naval exhaust systems.

Scenario B: High Static/Cyclic Loads (Aerospace & Energy)

Choose Inconel 718. When a part must withstand high RPMs or pressure without deforming, the yield strength of 718 is non-negotiable.

-

Typical Applications: Gas turbine blades, turbocharger rotors, high-pressure valves, rocket engine thrust chambers.

Scenario C: Fabrication and Weldability

Choose Inconel 625. Inconel 718 is susceptible to “strain-age cracking” during post-weld heat treatment if not handled precisely. In contrast, Inconel 625 is one of the most weldable superalloys available; it is resistant to intergranular cracking and requires no post-weld aging to restore corrosion resistance.

관련 Q&A

1. Which alloy is more difficult to machine, Inconel 625 or 718? Inconel 718 is generally more difficult to machine. Due to its precipitation-hardening capability, it work-hardens rapidly during cutting, leading to higher cutting forces and shorter tool life compared to the annealed Inconel 625.

2. Can Inconel 625 be used as a filler metal for welding Inconel 718? Yes. Inconel 625 filler metal (ERNiCrMo-3) is frequently used to weld Inconel 718 components, especially when the weld requires high ductility and corrosion resistance to prevent cracking in the Heat Affected Zone (HAZ).

3. Is Inconel 718 magnetic? No, both Inconel 625 and 718 are non-magnetic. However, heavy cold working or specific heat treatments can sometimes induce very slight magnetic permeability, but for most engineering purposes, they are considered non-magnetic.