The short answer is: Yes, regarding performance in extreme environments. However, if you factor in cost-efficiency for general applications, the answer becomes complicated. To make the right decision, we must dissect the chemical and physical differences between these two metal giants.

Defining the Alloys

To understand if Inconel 600 is better than SS 304, we first need to understand what they are.

-

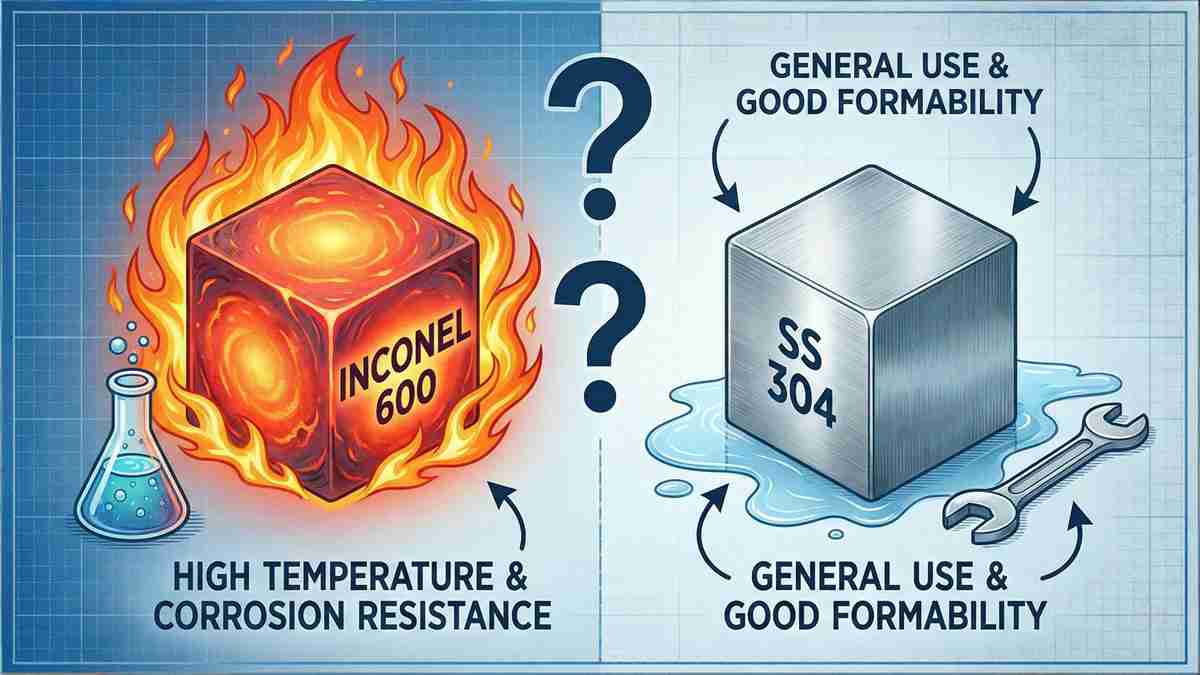

Stainless Steel 304 (UNS S30400): This is the “workhorse” of the steel industry. It is an austenitic stainless steel containing roughly 18% chromium and 8% nickel. It is ubiquitous, found in everything from kitchen sinks to industrial piping, offering solid corrosion resistance and formability at a reasonable price.

-

Inconel 600 (UNS N06600): This is a nickel-chromium superalloy. Unlike steel, its primary base is Nickel (>72%), supported by Chromium (14-17%) and Iron (6-10%). It is engineered specifically for extreme conditions where standard steels would fail.

1. High-Temperature Performance

When asking, “Is Inconel 600 better than SS 304 for heat applications?” the answer is an emphatic yes.

SS 304 has a maximum service temperature of roughly 870°C (1598°F) for intermittent service. However, pushed to these limits, it suffers from low creep strength and oxidation.

Inconel 600, conversely, is a beast in the heat. It maintains structural integrity and resists oxidation at temperatures up to 1093°C (2000°F). Because of its high nickel content, it does not suffer from the same thermal expansion issues as stainless steel, making it the superior choice for:

-

Heat treat furnace components.

-

Jet engine parts.

-

Chemical reactor vessels.

2. Corrosion Resistance

The most significant weakness of SS 304 is Chloride Stress Corrosion Cracking (CSCC). If you place 304 stainless steel in a saltwater environment or a process involving chlorides, tensile stress can cause sudden, catastrophic failure.

Is Inconel 600 better than SS 304 in these corrosive environments? Absolutely.

The high nickel content in Inconel 600 makes it virtually immune to chloride stress corrosion cracking. Furthermore, it offers superior resistance to:

-

Caustic alkalis (at high temperatures).

-

High-purity water environments (essential in nuclear reactors).

-

Organic and inorganic acids.

While SS 304 is adequate for mild oxidizing environments (like nitric acid), Inconel 600 is the necessary upgrade when the environment turns aggressive.

3. The Economic Reality

Here is where the argument shifts. If Inconel 600 is mechanically superior, why isn’t it used everywhere? The barrier is cost.

Inconel 600 contains over 70% nickel. Nickel is significantly more expensive than iron (the base of SS 304). Consequently, Inconel 600 can cost 5 to 10 times more than SS 304.

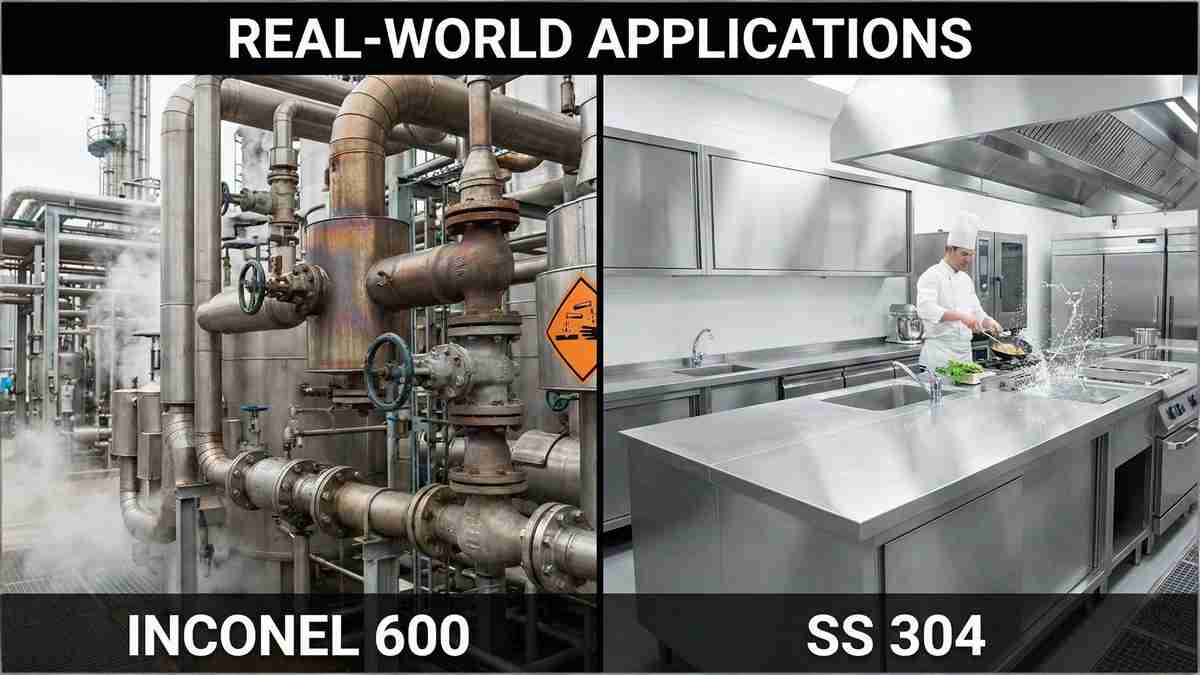

Therefore, is Inconel 600 better than SS 304 for a standard water pipe or a food processing conveyor? No. Using Inconel in these applications is fiscally irresponsible. SS 304 provides the necessary hygiene and durability without the astronomical price tag.

Comparison at a Glance

| Caraterística | Stainless Steel 304 | Inconel 600 | Winner |

| Base Element | Ferro (Fe) | Níquel (Ni) | N/A |

| Max Temp | ~870°C | ~1093°C | Inconel 600 |

| Resistência aos cloretos | Poor (Susceptible to cracking) | Excellent (Immune) | Inconel 600 |

| Custo | Low / Moderate | Very High | SS 304 |

| Machinability | Bom | Difficult (Work hardens) | SS 304 |

So, is Inconel 600 better than SS 304?

-

Escolha o Inconel 600 se: Your application involves temperatures above 800°C, high mechanical stress under heat, or exposure to chlorides and caustic alkalis.

-

Choose SS 304 if: You need a cost-effective, durable material for general chemical handling, food processing, or architectural structures where extreme heat is not a factor.

Perguntas frequentes (FAQs)

Q1: Can I weld Inconel 600 to SS 304?

Yes, dissimilar metal welding is possible. However, you must use the correct filler metal to prevent cracking and maintain corrosion resistance. Typically, a nickel-based filler metal like Inconel 82 (ERNiCr-3) is recommended when joining Inconel 600 to stainless steel 304.

Q2: Is Inconel 600 magnetic compared to SS 304?

Both alloys are generally non-magnetic. SS 304 is non-magnetic in its annealed state but may become slightly magnetic after cold working. Inconel 600 remains non-magnetic even at very low temperatures, which is a desirable trait for sensitive electronic applications.

Q3: Is Inconel 600 harder to machine than SS 304?

Yes. Inconel 600 has high strength and work-hardens rapidly during machining. It is significantly more difficult to cut and shape than SS 304, requiring heavy-duty tooling, slower speeds, and more aggressive feed rates to minimize work hardening.