Níquel 201

Nickel 201 is the low-carbon version of Nickel 200. Its extremely low carbon content (0.02% max) prevents embrittlement by intergranular carbon at elevated temperatures, making it the required choice for service above 600°F (315°C).

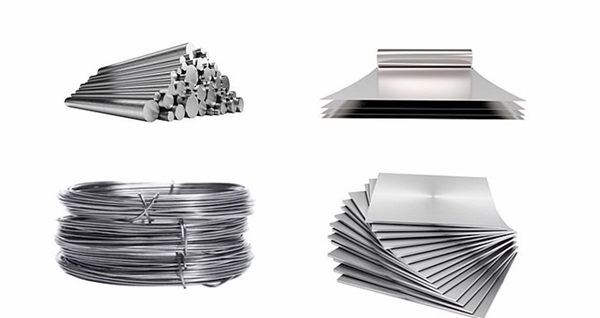

- Formas comuns: Plate, Sheet, Strip, Pipe, Tube, Bar, Wire.

- Caraterística principal: Resistance to graphitization and embrittlement at high temperatures.

- Physical Prop: High electrical and thermal conductivity; ferromagnetic.

- Temperature Limit: Preferred for service **above** 600°F (315°C).

While Nickel 201 shares the excellent corrosion resistance of Nickel 200, it should be specified for any application operating continuously above 600°F (315°C). The low carbon content is critical to maintaining ductility and avoiding premature failure in high-temperature caustic and electronic applications.

Estabilidade a altas temperaturas

The primary advantage over Nickel 200. It remains ductile and tough where Nickel 200 would become brittle due to carbon precipitation.

Caustic Resistance at Temp

Ideal for evaporators, reactors, and piping systems handling concentrated caustic soda at temperatures well above 600°F (315°C).

Electronic Purity

Used for electronic components that see high operating temperatures, such as anodes, cathodes, and magnetostrictive devices.

| Elemento | Conteúdo (%) |

|---|---|

| Nickel (Ni) + Cobalt | 99.0 min |

| Cobre (Cu) | 0.25 max |

| Ferro (Fe) | 0.40 max |

| Manganês (Mn) | 0.35 max |

| Carbono (C) | 0,02 max |

| Silício (Si) | 0.35 max |

| Sulfur (S) | 0,01 max |

*Note: The critically low carbon content is the defining characteristic of Nickel 201.

| Forma do produto | Normas ASTM / ASME |

|---|---|

| Tubos (sem costura) | ASTM B161, ASME SB161 |

| Placa, chapa, tira | ASTM B162, ASME SB162 |

| Bar e varão | ASTM B160, ASME SB160 |

| Acessórios | ASTM B366, ASME SB366 |

| Forjados | ASTM B564, ASME SB564 |

| Imóveis | Valores típicos (temperatura ambiente) |

|---|---|

| Resistência à tração | 50 - 70 ksi (345 - 485 MPa) |

| Resistência ao escoamento (0.2% Offset) | 12 - 25 ksi (83 - 172 MPa) |

| Alongamento | 45 - 60 % |

| Dureza (Rockwell B) | 40 - 70 HRB |

*Note: Due to its lower carbon content, Nickel 201 typically exhibits slightly lower strength and hardness than Nickel 200.

High-Temperature Caustic Service

Vessels and piping for caustic concentration and storage operating above 600°F (315°C).

Furnace Components

Combustion boats, furnace fixtures, and other components requiring ductility at elevated temperatures.

Electronic Components

Anode plates, passive cathodes, and plater bars used in high-temperature electronic devices.

Aerospace

Igniter components and other static aerospace parts exposed to high temperatures.

Need Nickel 201 for High-Temp Service?

We supply dual-certified Nickel 200/201 to meet your project's specific temperature requirements. Contact us for expert guidance and a competitive quote.

Obter um orçamento rápido