Inconel® Nickel Alloys

A family of austenitic nickel-chromium-based superalloys. Renowned for their exceptional performance in extreme environments involving high pressure, tremendous heat, and corrosive atmospheres.

Inconel 600

The standard engineering material for applications requiring resistance to corrosion and heat. excellent mechanical properties and presents the desirable combination of high strength and good workability.

Inconel 601

A nickel-chromium alloy with an addition of Aluminum for outstanding resistance to high-temperature oxidation. It resists spalling even under severe thermal cycling conditions.

Inconel 617

Combines metallurgical stability, strength, and oxidation resistance at high temperatures. Widely used in gas turbines and petrochemical plants for combustion cans and ducts.

Inconel 625

High strength and outstanding corrosion resistance without heat treatment. The addition of molybdenum and niobium acts to stiffen the alloy matrix, providing high fatigue strength.

Inconel 718

The workhorse of the aerospace industry. A precipitation-hardenable alloy with exceptionally high yield, tensile, and creep-rupture properties at temperatures up to 1300°F.

Inconel X-750

Similar to Alloy 600 but made precipitation-hardenable by additions of aluminum and titanium. Commonly used for springs, fasteners, and gas turbine blades requiring high relaxation resistance.

Why Choose Inconel Alloys?

Inconel alloys are classified as Superalloys. They are specifically engineered to maintain structural integrity in environments where lesser metals would melt, oxidize, or succumb to creep deformation.

When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. This makes them indispensable in jet engines, chemical processing reactors, and marine environments.

| Liga metálica | N.º UNS. | Key Characteristic | Aplicação típica |

|---|---|---|---|

| Inconel 600 | N06600 | Standard heat & corrosion resistance. Immune to chloride stress cracking. | Heat treating muffles, chemical processing. |

| Inconel 601 | N06601 | Maximum oxidation resistance up to 2200°F (1200°C). | Radiant tubes, thermal reactors, igniters. |

| Inconel 625 | N06625 | Excellent aqueous corrosion resistance + high strength. | Marine exhaust, seawater piping, pollution control. |

| Inconel 718 | N07718 | Highest strength (Age-Hardenable). Excellent weldability. | Jet engine disks, liquid fuel rockets, bolts. |

Aerospace

Turbine blades, exhaust systems, and engine thrust reversers.

Produção de energia

Nuclear reactor core components and gas turbine engines.

Processamento químico

Vessels for handling fatty acids, hydrofluoric acid, and caustic solutions.

Looking for High-Performance Superalloys?

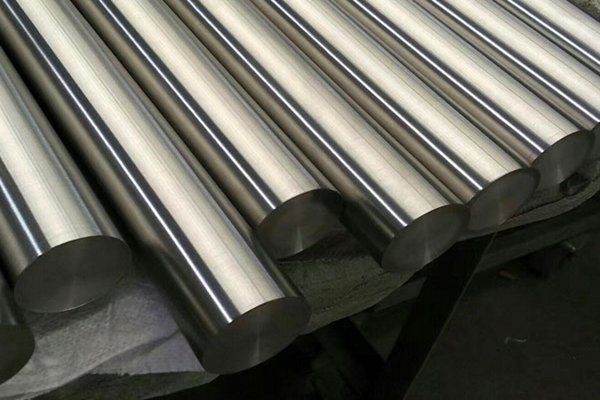

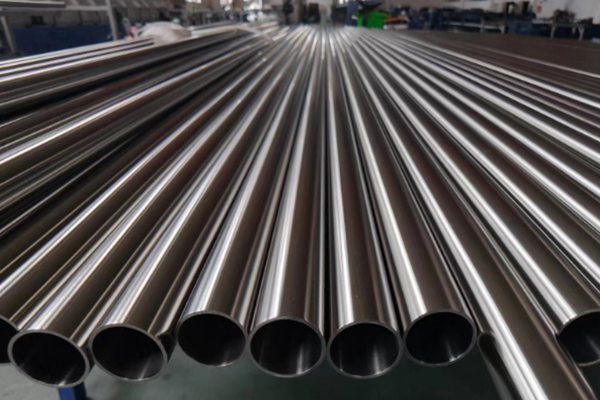

We stock a wide range of Inconel sheet, plate, bar, and pipe. Mill test reports (MTR) available with every shipment.

Pedir um orçamento