Monel® Metal Alloys

Nickel-Copper superalloys famous for their high strength and toughness over a wide temperature range, and exceptional resistance to many corrosive environments, particularly sea water and hydrofluoric acid.

Monel 400

The standard Nickel-Copper alloy (UNS N04400). It offers great resistance to sea water and steam at high temperatures, as well as to salt and caustic solutions.

Monel R-405

The free-machining version of Monel 400 (UNS N04405). Controlled sulfur is added to create sulfide inclusions, which act as chip breakers during machining operations.

Monel K-500

A precipitation-hardenable Nickel-Copper alloy (UNS N05500). By adding Aluminum and Titanium, it combines the corrosion resistance of 400 with 3x the yield strength and hardness.

Why Choose Monel Alloys?

Monel alloys are unique because they contain a large amount of Copper (about 30%) in addition to Nickel (about 63%). This composition makes them superior to commercially pure Nickel in resisting corrosion by rapidly flowing brackish water or seawater.

They are also one of the few alloys that can withstand Hydrofluoric Acid, making them indispensable in the chemical processing industry.

| Liga metálica | Key Characteristics | Machinability | Aplicação típica |

|---|---|---|---|

| Monel 400 | Solid solution alloy. High strength and toughness over wide temperature range. Excellent corrosion resistance. | Bom | Marine fixtures, Chemical piping, Heat exchangers. |

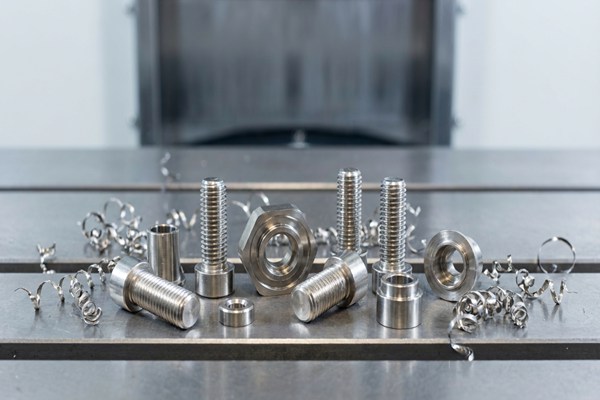

| Monel R-405 | Similar to 400 but with added Sulfur for enhanced machinability. | Excelente | Automatic screw machine parts, Fasteners, Valve inserts. |

| Monel K-500 | Precipitation hardenable. 3x stronger than 400. Non-magnetic down to -200°F. | Fair (Hard) | Propeller shafts, Pump shafts, Oil well drill collars. |

Marine Engineering

Propellers, shafts, and piping systems exposed to sea water.

Petróleo e gás

Drill collars and instruments requiring non-magnetic properties.

Processamento químico

Handling hydrofluoric acid, sulfuric acid, and alkalis.

Can Monel be welded?

Yes, Monel 400 has excellent weldability. Monel K-500 can also be welded, but it requires post-weld heat treatment (PWHT) to restore its strength and ductility.

What is the difference between Monel 400 and K-500?

K-500 has Aluminum and Titanium added, allowing it to be heat-treated (aged) for much higher strength and hardness. Monel 400 is strictly a solid-solution alloy and cannot be hardened by heat treatment, only by cold working.

Looking for Monel Stock?

We carry a comprehensive inventory of Monel 400 piping and Monel K-500 bars.

Pedir um orçamento