In the realm of nickel-based superalloys, the Nimonic series represents a cornerstone of high-temperature material engineering. Among the most frequently compared grades are Nimonic 75 (UNS N06075) and Nimonic 80A (UNS N07080). While both alloys share a nickel-chromium base designed for extreme environments, their metallurgical structures and performance envelopes differ significantly due to their strengthening mechanisms. This article provides a technical deep dive into their differences to assist engineers and procurement specialists in making informed decisions.

Nimonic 75 vs 80A Comparison

The fundamental distinction between Nimonic 75 and Nimonic 80A lies in their chemical composition and the resulting strengthening method.

-

Nimonic 75 is a solid-solution strengthened alloy. It is essentially an 80/20 nickel-chromium matrix with controlled additions of titanium and carbon. It is primarily valued for its excellent oxidation resistance and fabricability rather than high-load mechanical strength.

-

Nimonic 80A is a precipitation-hardenable (age-hardened) alloy. By increasing the levels of aluminum and titanium, it forms a gamma prime (γ′) intermetallic phase (Ni3(Al,Ti)) during heat treatment. This phase acts as a barrier to dislocation movement, significantly enhancing its creep and fatigue resistance.

Table 1: Chemical Composition Comparison (Typical %)

| Elemento | Nimonic 75 (Alloy 75) | Nimonic 80A (Alloy 80A) |

| Níquel (Ni) | Equilíbrio | Equilíbrio |

| Crómio (Cr) | 18.0 – 21.0 | 18.0 – 21.0 |

| Titânio (Ti) | 0.2 – 0.6 | 1.8 – 2.7 |

| Alumínio (Al) | – | 1.0 – 1.8 |

| Ferro (Fe) | 5.0 max | 3.0 max |

| Carbono (C) | 0.08 – 0.15 | 0.10 max |

Table 2: Mechanical Properties at Room Temperature

| Imóveis | Nimonic 75 (Annealed) | Nimonic 80A (Age Hardened) |

| Tensile Strength (MPa) | ~750 | ~930 – 1000 |

| 0.2% Yield Strength (MPa) | ~300 | ~600 – 700 |

| Elongation (%) | 35 – 45 | 20 – 30 |

| Hardness (HB) | 150 – 200 | 250 – 300 |

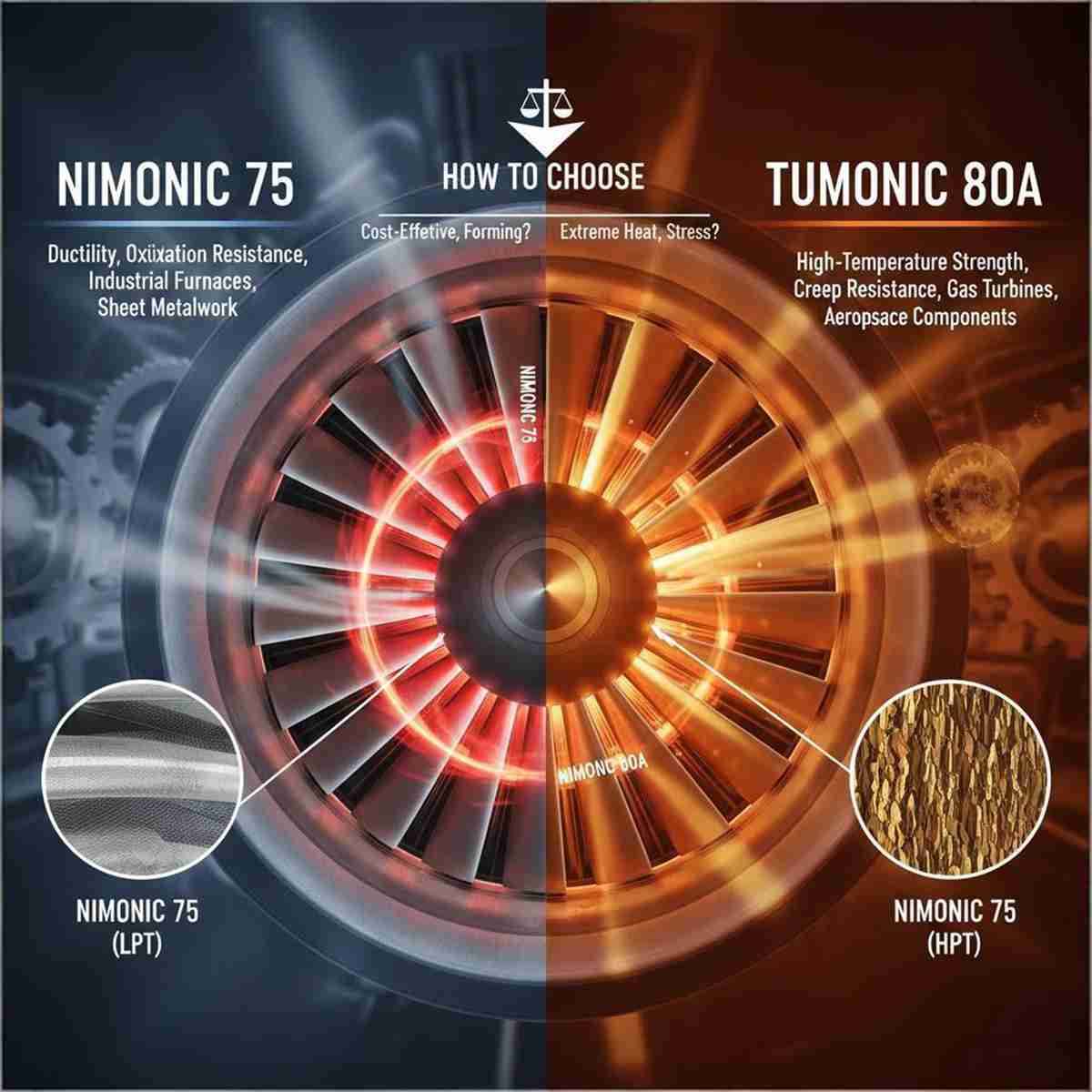

Nimonic 75 vs 80A: How to Choose?

Selecting between these two alloys depends on the primary failure mode of the application: Mechanical Stress vs. Environmental Oxidation.

1. Temperature vs. Load

If your application involves temperatures up to 1000∘C but requires relatively low mechanical stress (e.g., furnace components), Nimonic 75 is the superior choice. Its simpler chemistry makes it more stable against oxidation and scaling in various industrial atmospheres.

Conversely, for applications where the material must resist deformation under high loads at temperatures up to 815∘C, Nimonic 80A is indispensable. Its high creep-rupture strength ensures dimensional stability under prolonged thermal and mechanical stress.

2. Fabricability and Welding

Nimonic 75 is renowned for its excellent weldability and ease of cold forming. It can be joined using most standard fusion welding techniques (TIG/MIG) without significant risk of cracking.

Nimonic 80A, being a precipitation-hardened alloy, is more sensitive. It requires precise solution treatment before welding and post-weld heat treatment (PWHT) to prevent strain-age cracking. If complex fabrication or sheet metal work is required, Alloy 75 is significantly more user-friendly.

3. Eficiência de custos

Due to the absence of aluminum and lower titanium content, Nimonic 75 is generally more cost-effective. Use it unless the mechanical demands of the project strictly require the high-temperature strength of 80A.

Nimonic 75 vs 80A Turbine Blade Use

The history of gas turbine engineering is essentially the history of the Nimonic series. In early jet engines (like the Whittle engine), Nimonic 75 was the original material for turbine blades. however, as engine temperatures and rotational speeds increased, Alloy 75 reached its mechanical limit.

The Shift to Nimonic 80A

Modern turbine blade design requires materials that can withstand the centrifugal forces of high-speed rotation. Nimonic 80A became the industry standard for:

-

High-Pressure Turbine Blades: Where creep resistance is the critical factor.

-

Exhaust Valves: In high-performance internal combustion engines (especially in motorsport).

-

Turbine Discs and Rings: Requiring high fatigue life.

While Nimonic 75 has largely been phased out of rotating blade applications, it remains a “workhorse” for static components in the turbine section. It is extensively used for combustion chamber liners, exhaust ducting, and flame tubes, where its ability to resist oxidation and thermal cycling is more valuable than its creep strength.

Perguntas e respostas relacionadas

Q1: What is the maximum service temperature for Nimonic 80A? For high-stress applications like turbine blades, Nimonic 80A is typically limited to 815∘C (1500∘F). Above this, the γ′ precipitates begin to coarsen, leading to a loss in mechanical strength.

Q2: Can Nimonic 75 be hardened by heat treatment? No, Nimonic 75 is a solid-solution alloy and cannot be significantly hardened by heat treatment. It can, however, be strengthened through cold working (work hardening) if necessary.

Q3: Which alloy is better for resistance to sulfuric atmospheres? Both alloys offer good resistance due to their high chromium content. However, Nimonic 75 is often preferred in industrial furnace environments because its surface oxide layer (chromia) is exceptionally stable and less prone to spalling during thermal cycling.