In the demanding realms of marine engineering and chemical processing, material failure is not an option. Engineers frequently face the dilemma of choosing between two titans of the non-ferrous world: Монель 400 (UNS N04400) and Copper-Nickel 70/30 (C71500). While both rely on the synergy of copper and nickel to fight corrosion, their distinct compositions creates vastly different performance profiles.

This guide provides a technical breakdown to resolve the Monel 400 vs Copper-Nickel 70/30 debate, helping you optimize for cost, longevity, and mechanical integrity.

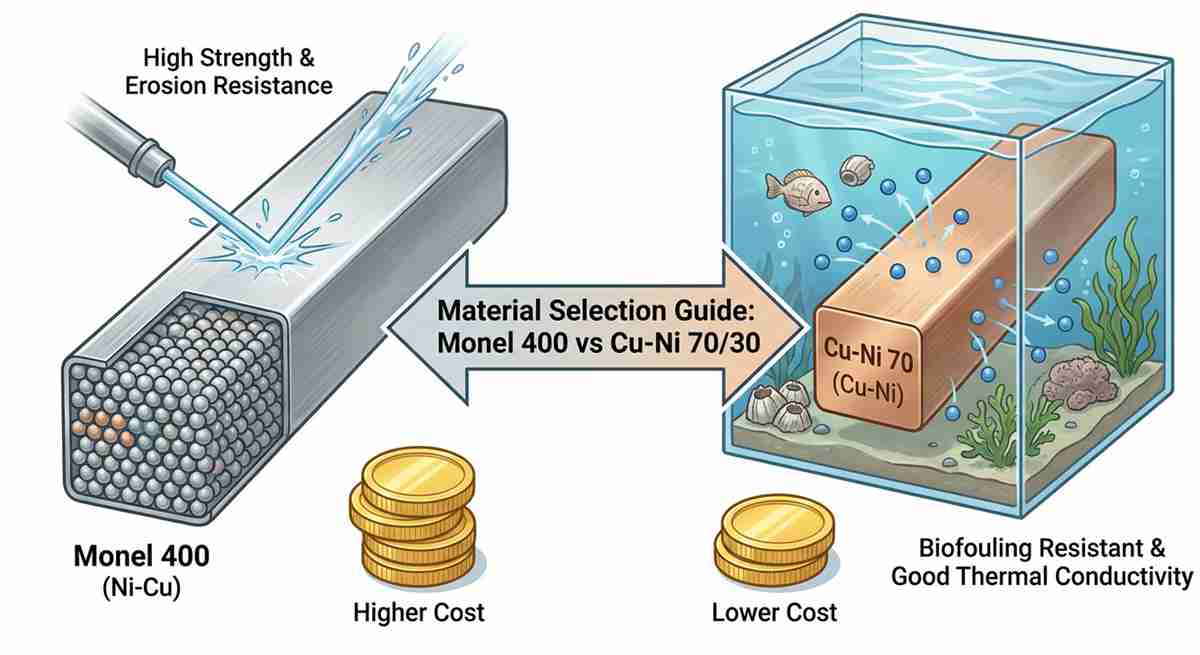

Monel 400 vs Cu-Ni 70/30 comparison

The fundamental difference lies in the “base” metal. Монель 400 is a nickel-based alloy (approx. 63-70% Nickel, 30% Copper), whereas Copper-Nickel 70/30 is copper-based (70% Copper, 30% Nickel). This inversion of ratios dictates their mechanical limits.

Mechanical Strength & Durability

Monel 400 is the clear winner in pure strength. As a solid-solution binary alloy, it boasts tensile strengths ranging from 70-120 ksi (480-830 MPa), nearly double that of Cu-Ni 70/30, which typically sits around 50-60 ksi. If your application involves high-pressure valve stems or pump shafts subjected to torque, Monel 400 provides the necessary yield strength that Cu-Ni cannot.

Thermal Properties

However, strength isn’t everything. Cu-Ni 70/30 retains excellent thermal conductivity (approx. 29 W/m·K), making it the superior choice for heat transfer applications like condenser tubes and shell-and-tube heat exchangers. Monel 400, while thermally stable, is less conductive and is often reserved for structural components rather than heat transfer surfaces.

| Характеристика | Монель 400 (UNS N04400) | Copper-Nickel 70/30 (C71500) |

| Base Metal | Nickel (~67%) | Copper (~70%) |

| Прочность на разрыв | High (80,000 psi avg) | Moderate (55,000 psi avg) |

| Hardness | High (Rockwell B 60-80) | Moderate (Rockwell B 40-50) |

| Cost | High (Premium Alloy) | Moderate (Cost-Effective) |

Monel 400 vs Cu-Ni 70/30 how to choose

Selecting between these two alloys often comes down to balancing budget constraints against environmental intensity.

1. The Cost-Benefit Analysis

Monel 400 is significantly more expensive than Cu-Ni 70/30 due to the high market price of nickel. For large-scale piping networks spanning kilometers, Cu-Ni 70/30 is the standard economical choice. It offers a “good enough” lifespan for general seawater piping without the exorbitant cost of Monel. Use Monel 400 selectively for critical failure points—valves, instrumentation, and fasteners—where replacement is difficult.

2.Manufacturing and Fabrication

If your project requires extensive welding and forming, Cu-Ni 70/30 is generally more forgiving and easier to fabricate. Monel 400 allows for welding but requires strict cleanliness to avoid embrittlement and specific filler metals (like Monel 60) to match its strength.

Decision Matrix:

- Choose Monel 400 if: You need high strength, resistance to high-velocity erosion, or exposure to harsh chemicals like hydrofluoric acid.

- Choose Cu-Ni 70/30 if: You are designing heat exchangers, need natural biofouling resistance, or require a cost-effective solution for static seawater lines.

Monel 400 vs Cu-Ni for seawater corrosion

This is the critical battleground. While both are “marine grade,” they interact with seawater differently.

Velocity and Erosion

Монель 400 is the king of high-velocity environments. It thrives in rapidly flowing seawater (up to 45 m/s in some cases) without suffering from erosion-corrosion. This makes it ideal for pump impellers, propellers, and bow thrusters.

Conversely, Cu-Ni 70/30 has a turbulence limit. While it handles flow better than the cheaper 90/10 grade, it can still suffer impingement attack if water velocity exceeds 3-4 m/s.

Biofouling Resistance

Here, Copper-Nickel 70/30 holds a unique advantage. The high copper content releases free copper ions into the boundary layer of the water, which naturally inhibits the growth of barnacles and algae (biofouling).

Монель 400, being nickel-dominant, does not possess this anti-fouling property. Marine organisms will grow on Monel surfaces. While the Monel underneath won’t corrode, the buildup can cause flow blockages or crevice corrosion issues if not cleaned.

Stagnant Water Conditions

In stagnant or slow-moving water, Monel 400 can be susceptible to pitting corrosion, especially if biofouling creates crevices. Cu-Ni 70/30 is generally more resistant to pitting in quiet waters, making it safer for systems with intermittent flow.

Frequently Asked Questions (FAQ)

1. Can Monel 400 replace Cu-Ni 70/30 in heat exchangers?

While Monel 400 can physically replace Cu-Ni, it is often not recommended. Monel has lower thermal conductivity, which reduces heat transfer efficiency, and its significantly higher cost makes it uneconomical for tubing unless extreme pressure or chemical contaminants (like HF acid) are present.

2.Which alloy is better for propeller shafts?

Monel 400 (or its age-hardened version, Monel K-500) is far superior for shafts. The high torque loads on a propeller shaft require the high tensile strength of Monel. Cu-Ni 70/30 is too soft for high-stress structural applications like shafting.

3. Does Monel 400 rust in saltwater?

Monel 400 is virtually immune to general “rusting” (iron oxide formation) and chloride stress-corrosion cracking in seawater. However, it may tarnish or turn green (patina) over time. In stagnant water, it can suffer from localized pitting, so it is best used in flowing systems.