Your Trusted Partner

For Nickel Alloy Materials

From raw materials to finished products, we deliver excellence. Specializing in nickel alloy bars, sheets, tubes, and wires, as well as precision custom castings for diverse industries across the globe.

Our impact

Comprehensive Nickel Alloy Solutions

At 28Nickel, we are dedicated to powering industries with high-performance materials. From raw material supply to precision castings, we provide tailored solutions that meet the rigorous demands of extreme environments.

Custom Castings & Fabrication

We turn your specifications into reality. Specializing in investment casting and sand casting, we deliver precision nickel alloy components tailored to your exact drawings and technical requirements.

Global Material Supply

nickel alloys in bars, sheets, tubes, and wires. We maintain a robust supply chain to ensure fast delivery of high-quality materials for petrochemical, aerospace, and energy sectors.

Rigorous Quality Control

Every product undergoes strict inspection, including chemical analysis and mechanical testing. We provide full traceability and Mill Test Certificates (MTC) with every shipment.

Why Us

Your Strategic Partner for High-Performance Alloys

At 28Nickel, we bridge the gap between top-tier manufacturing and global demand. We don't just supply metal; we provide technical expertise and tailored solutions. From selecting the right grade to delivering custom castings, our agile team ensures your project requirements are met with precision and speed.

10+

Years of Industrial Experience

Although 28Nickel is a new chapter, our team brings decades of deep industry knowledge in nickel alloys and metallurgy to serve your business.

Uncompromising Quality & Dedicated Service

At 28Nickel, we believe quality is the foundation of trust. We adhere to strict international standards (ASTM, ASME, ISO) to ensure every bar, sheet, and casting meets your exact specifications. With full material traceability and rigorous pre-shipment inspections, we deliver the reliability your critical projects demand.

Nimonic 75 vs Nimonic 80A

In the realm of nickel-based superalloys, the Nimonic series represents a cornerstone of high-temperature material engineering. Among the most frequently compared grades are Nimonic 75

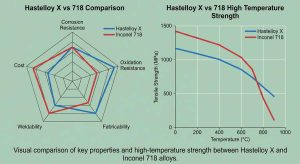

Hastelloy X vs Inconel 718

Choosing the right nickel-based superalloy is critical for aerospace, power generation, and chemical processing. Two of the most prominent contenders are Hastelloy X and Inconel

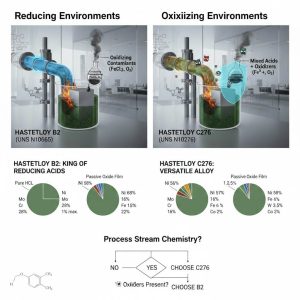

Hastelloy B2 vs Hastelloy C276

In the world of high-performance nickel alloys, choosing between Hastelloy B2 (UNS N10665) and Hastelloy C276 (UNS N10276) can be the difference between a decade