Choosing the wrong grade can lead to catastrophic component failure—either through high-temperature rupture or aggressive chemical corrosion. This guide breaks down the critical differences in Incoloy 800 vs 825, analyzing their chemical composition, mechanical properties, and ideal service environments.

The Core Distinction: Heat vs. Corrosion

To simplify the selection process, categorize the alloys by their primary strength:

-

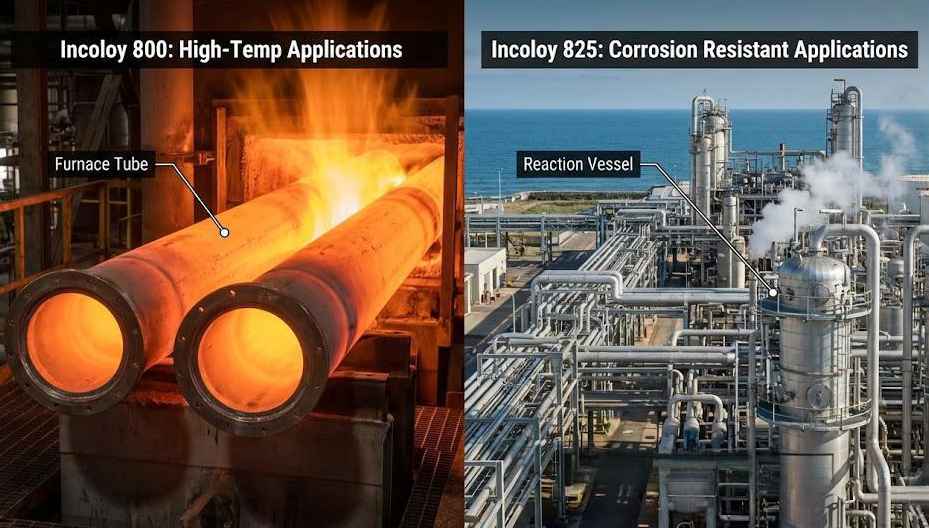

Incoloy 800 (UNS N08800): Engineered for High-Temperature Stability. It is the go-to choice for resistance to oxidation and carburization in heat-treating atmospheres.

-

Incoloy 825 (UNS N08825): Engineered for Aggressive Wet Corrosion. With added molybdenum and copper, it excels in reducing acids and oxidizing chemicals where standard stainless steels fail.

Chemical Composition Analysis

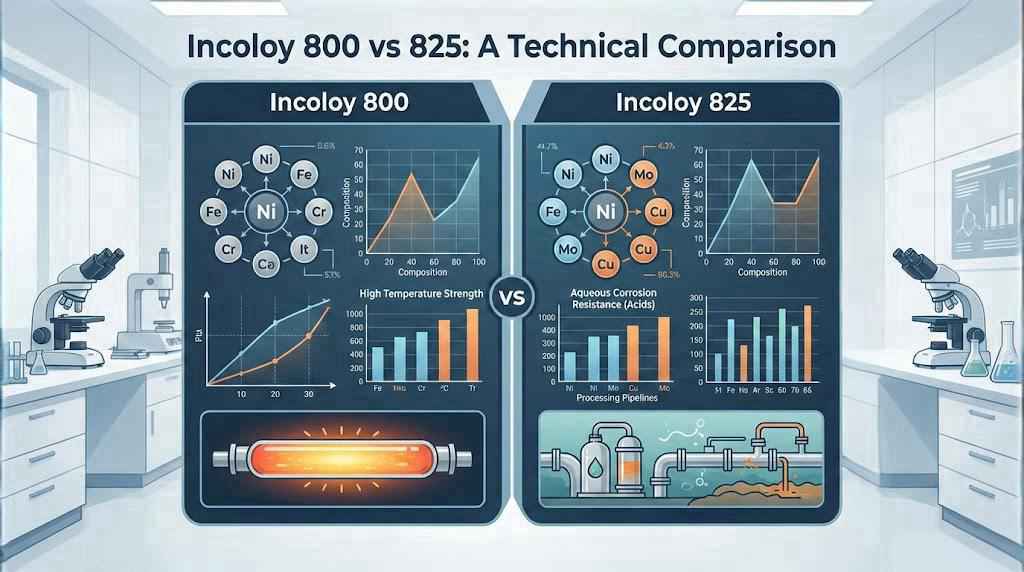

The physical properties of these alloys are dictated by their elemental makeup. The primary differentiator in the Incoloy 800 vs 825 comparison is the addition of Molybdenum and Copper in the 825 grade.

| Element | Incoloy 800 (Typical %) | Incoloy 825 (Typical %) | Impact on Performance |

| Nickel (Ni) | 30.0 – 35.0 | 38.0 – 46.0 | Higher Ni in 825 provides immunity to Chloride Stress Corrosion Cracking. |

| Chromium (Cr) | 19.0 – 23.0 | 19.5 – 23.5 | Both offer excellent resistance to oxidizing environments. |

| Iron (Fe) | Balance | Balance (min 22%) | Provides cost-effectiveness compared to pure Nickel alloys. |

| Molybdenum (Mo) | N/A | 2.5 – 3.5 | Critical Difference: Gives 825 resistance to pitting and crevice corrosion. |

| Copper (Cu) | N/A | 1.5 – 3.0 | Critical Difference: Gives 825 resistance to sulfuric acid. |

| Titanium (Ti) | 0.15 – 0.60 | 0.6 – 1.2 | Stabilizes the alloy against sensitization. |

Incoloy 800

Incoloy 800 is defined by its ability to maintain a stable austenitic structure during prolonged exposure to elevated temperatures. It resists embrittlement (the formation of the sigma phase) better than many 300-series stainless steels.

Key Characteristics:

-

Oxidation Resistance: The high chromium and nickel content create a tight oxide scale that protects the metal, even in cyclical heating and cooling environments.

-

Carburization Resistance: Ideal for petrochemical cracking furnaces where carbon absorption can cause failure.

-

Common Applications: Heat exchanger tubing, carburizing fixtures, ethylene furnace quench boilers, and steam superheater tubing.

Note: For applications strictly above 1100°F (593°C) requiring creep-rupture strength, engineers often opt for the solution-annealed variants, Incoloy 800H or 800HT.

Incoloy 825

When the environment shifts from “hot” to “corrosive,” Incoloy 825 becomes the superior candidate. The inclusion of molybdenum and copper drastically alters the alloy’s capabilities, specifically in reducing environments.

Key Characteristics:

-

Acid Resistance: Exceptional performance in sulfuric and phosphoric acids. The copper content is specifically added to combat sulfuric acid attack.

-

Stress Corrosion Cracking (SCC): The higher nickel content (up to 46%) makes Incoloy 825 virtually immune to chloride-ion SCC, a common killer of stainless steel in marine or brine environments.

-

Pitting Resistance: Molybdenum ensures the alloy resists localized pitting in chloride-containing media.

-

Common Applications: Chemical processing equipment, pollution control (scrubbers), oil and gas recovery (sour gas service), and pickling tank heaters.

In a cost analysis of Incoloy 800 vs 825, Incoloy 825 is generally more expensive. This premium is due to the higher nickel content and the addition of expensive alloying elements like molybdenum.The decision between these two superalloys is rarely about which is “better,” but rather which matches the failure mode you are trying to prevent.

-

Choose Incoloy 800 if your primary concern is heat, oxidation, and structural integrity at high temperatures.

-

Choose Incoloy 825 if your primary concern is chemical attack, acids, or stress corrosion cracking in wet environments.

Frequently Asked Questions (FAQs)

Q1: Can Incoloy 825 be used in high-temperature applications like Incoloy 800?

While Incoloy 825 has good high-temperature strength, it is not optimized for it. Above 1000°F (540°C), microstructural changes can occur that reduce ductility and impact strength. For applications exceeding this temperature, Incoloy 800 (or 800H/HT) is the correct specification.

Q2: Which alloy is better for marine environments, 800 or 825?

Incoloy 825 is significantly better for marine environments. The presence of Molybdenum and higher Nickel gives it superior resistance to saltwater pitting and chloride stress corrosion cracking. Incoloy 800 may suffer from pitting in stagnant seawater.

Q3: Is Incoloy 800 magnetic?

No. Both Incoloy 800 and 825 possess a stable face-centered cubic (austenitic) structure, meaning they remain non-magnetic even after heavy cold working. This makes them suitable for applications requiring low magnetic permeability.