When selecting materials for extreme environments, the decision often narrows down to two titans of the nickel-alloy world: Inconel 625 and Hastelloy C276. Both are widely respected superalloys, renowned for their ability to withstand environments that would destroy standard stainless steels in hours. However, for procurement officers and engineers, treating them as interchangeable is a costly mistake.

While they share a Nickel-Chromium-Molybdenum base, their distinct microstructures dictate where they thrive—and where they fail.

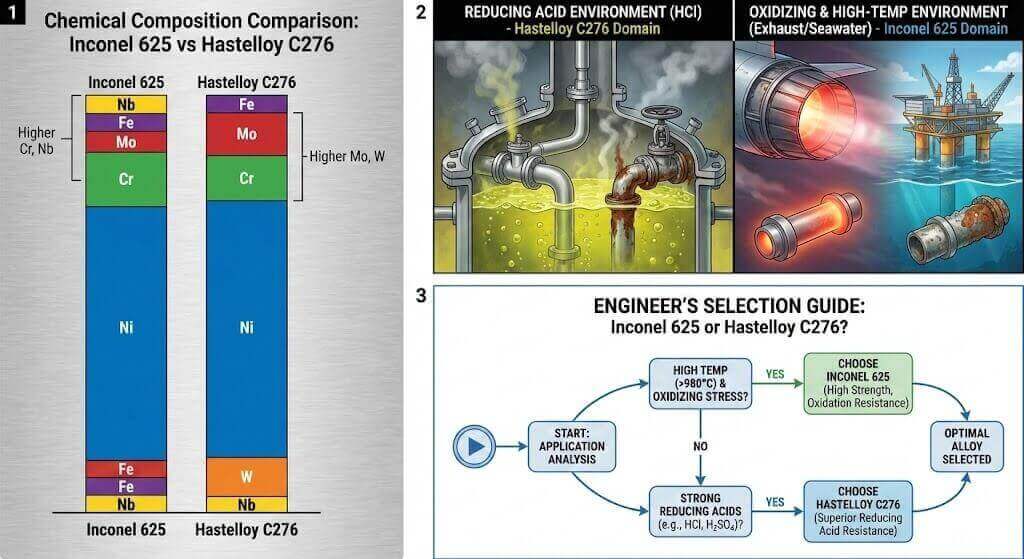

Inconel 625 vs Hastelloy C276 comparison

To understand the difference, we must look at the metallurgy. Both alloys rely on the Nickel matrix for stability, but their secondary elements drive their performance.

Inconel 625 (UNS N06625) is fundamentally a Nickel-Chromium-Molybdenum alloy with a critical addition: Niobium (often listed with Tantalum). The Niobium acts as a stiffener for the alloy matrix, providing exceptional yield and tensile strength without the need for heat-treating precipitation.

Hastelloy C276 (UNS N10276) takes a different path. It is a Nickel-Molybdenum-Chromium alloy fortified with Tungsten. It lowers the Chromium content slightly compared to 625 but significantly boosts Molybdenum and adds Tungsten. This shift prioritizes chemical inertness over pure mechanical muscle.

Key Mechanical Differences:

-

Yield Strength: Inconel 625 generally offers higher tensile and yield strength than C276, largely due to the Niobium stiffening effect.

-

Fabrication: Both have good ductility, but 625’s work-hardening rate is high, requiring rigid tooling. C276 is well-known for excellent weldability with minimal grain boundary precipitation.

Inconel 625 vs Hastelloy C276 corrosion resistance

This is the most critical differentiator. While both resist corrosion, they defend against different types of chemical attacks.

Hastelloy C276: The Reducing Acid Specialist Hastelloy C276 is arguably the premier alloy for the chemical processing industry. Its high Molybdenum (15-17%) and Tungsten content give it unrivaled resistance to reducing environments.

-

Pitting & Crevice Corrosion: C276 has a high PREN (Pitting Resistance Equivalent Number), making it immune to localized attacks in hot, chloride-rich solutions.

-

Acids: It excels in handling hydrochloric acid, sulfuric acid, and hypochlorites. It is one of the few materials that withstands wet chlorine gas and chlorine dioxide.

Inconel 625: The Oxidizing & High-Temp Specialist Inconel 625 has a higher Chromium content (20-23%) compared to C276 (14.5-16.5%). Chromium is the element that combats oxidizing environments.

-

Oxidation: 625 forms a stable passivating oxide layer that protects the metal in highly oxidizing acid environments (like Nitric acid) and high-temperature oxidation scenarios (jet engines).

-

Seawater: 625 is virtually immune to chloride-ion stress-corrosion cracking and is a standard material for marine exhaust systems and subsea components.

The Verdict: If the environment involves wet chlorine or strong reducing acids (HCl), Hastelloy C276 is the winner. If the environment involves oxidizing acids, high-temperature exhaust gases, or seawater, Inconel 625 is often the superior (and sometimes more cost-effective) choice.

Inconel 625 vs Hastelloy C276 how to choose

Making the final selection requires balancing three factors: Temperature, Chemistry, and Budget.

-

Analyze the Temperature & Stress: If your application involves high heat combined with high mechanical stress (e.g., aerospace ducting, turbine shroud rings), Inconel 625 is the preferred choice. Its creep-rupture strength at elevated temperatures is superior.

-

Analyze the Chemical Media: For mixed acid streams, particularly in pollution control (FGD systems) or waste treatment where the chemical composition fluctuates between oxidizing and reducing, Hastelloy C276 offers the safest “insurance policy” due to its versatility in severe media.

-

Cost Considerations: Generally, Hastelloy C276 is more expensive than Inconel 625. This is due to the higher cost of Molybdenum and Tungsten, as well as the complexity of its production. If Inconel 625 offers sufficient corrosion resistance for your specific media (e.g., standard seawater), choosing C276 may be unnecessary over-engineering.

Related Q&A

Q1: Can Inconel 625 be welded to Hastelloy C276?

Yes, dissimilar welding is possible between these two superalloys. Typically, a filler metal matching the more corrosion-resistant alloy (in this case, C276 or a specialized welding product like Hastelloy C-22) is recommended to ensure the weld seam does not become the weak point in corrosive service.

Q2: Which alloy is better for Hydrochloric Acid (HCl)?

Hastelloy C276 is significantly better for Hydrochloric Acid. The high Molybdenum content in C276 is specifically designed to resist the attack of reducing acids like HCl, whereas Inconel 625 may suffer faster degradation in concentrated HCl solutions.

Q3: Are these alloys magnetic?

No. Both Inconel 625 and Hastelloy C276 are austenitic nickel-based alloys and are non-magnetic. This makes them suitable for applications where magnetic interference must be minimized, such as in sensitive electronic housings or submarine auxiliary equipment.