When selecting high-performance nickel alloys for severe environments, engineers often narrow their choice down to two “siblings” in the Monel family: Monel 400 (UNS N04400) and Monel K-500 (UNS N05500). While they share a chemical lineage, their mechanical behaviors and specific applications differ largely due to a single metallurgical process: precipitation hardening.

Understanding the distinct properties of these two alloys is critical for ensuring component longevity and avoiding costly material failures.

Monel 400 vs K500 comparison

The fundamental difference between Monel 400 and Monel K-500 lies in their strengthening mechanisms and magnetic permeability.

1. Chemical Composition and Strengthening Monel 400 is a solid-solution binary alloy consisting of roughly 63% Nickel and 30-34% Copper. Its strength is derived solely from the hardening effect of the copper atoms within the nickel lattice. It remains ductile and tough across a wide temperature range.

Monel K-500 maintains the same basic Ni-Cu ratio but adds precise amounts of Aluminum (2.3-3.15%) and Titanium (0.35-0.85%). These additions allow the alloy to undergo precipitation hardening (age hardening). When heat-treated, submicroscopic gamma-prime particles precipitate throughout the matrix, effectively locking the grain structure. The result? Monel K-500 boasts a yield strength approximately 3 times higher and a tensile strength 2 times higher than Monel 400.

2. Magnetic Permeability For applications involving sensitive electronic sensors or compasses, this distinction is vital:

-

Monel 400: Typically exhibits some magnetic properties at room temperature (its Curie temperature is near ambient).

-

Monel K-500: Is virtually non-magnetic, even at temperatures as low as -100°C (-150°F).

The image below provides a visual comparison of these key differences.

Monel 400 vs K500 how to choose

Choosing between these two grades requires balancing mechanical demands against fabrication complexity.

-

Select Monel 400 if:

-

Formability is a priority: You need to cold-form, deep-draw, or bend the material into complex shapes (e.g., heat exchanger tubing).

-

Welding simplicity: You require a material that is easily welded without the need for rigorous post-weld heat treatment (PWHT) to restore ductility.

-

Chemical media: The application involves Hydrofluoric (HF) acid alkylation units, where Monel 400 is the industry standard.

-

-

Select Monel K-500 if:

-

High Fatigue Strength is needed: The component will be subjected to cyclic loading or high vibration (e.g., centrifugal pump shafts).

-

Wear Resistance: The part requires high hardness (Rockwell C) to resist galling or erosion.

-

Non-Magnetic Properties: You are designing for down-hole oil & gas drilling instruments or mine-sweeping equipment where magnetic interference is unacceptable.

-

Monel 400 vs K500 for marine service

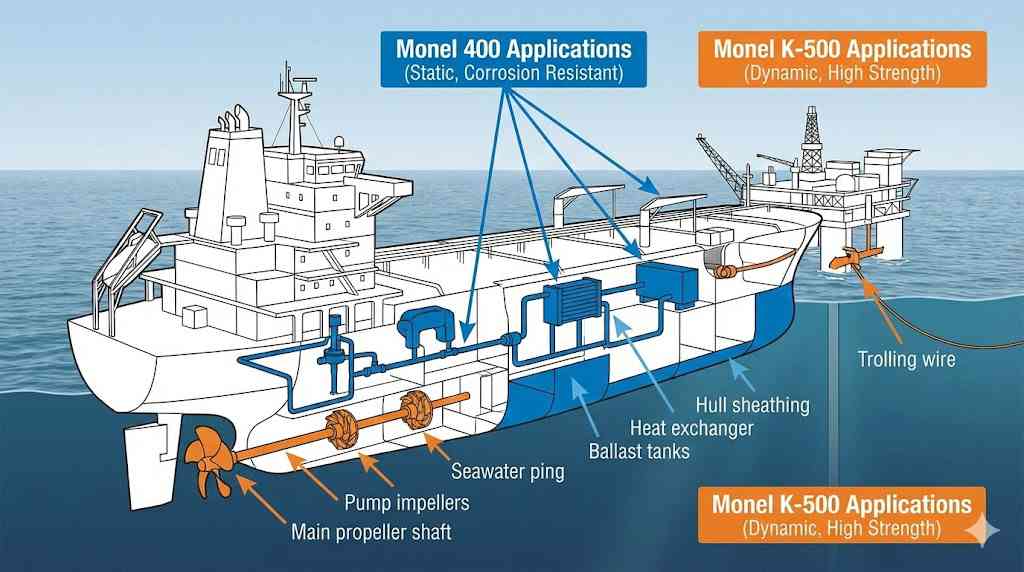

Both alloys are legendary in marine engineering for their near-total immunity to chloride-ion stress corrosion cracking and resistance to rapidly flowing seawater. However, they serve different roles on a vessel or offshore platform.

Monel 400 is the workhorse for “static” or fluid-handling components. It is extensively used for seawater piping systems, fuel and water tanks, and underwater sheathing. Its ability to resist bio-fouling and pitting makes it ideal for components in constant contact with stagnant seawater.

Monel K-500 is the specialist for “dynamic” high-stress components. Because of its immense fatigue strength, it is the material of choice for propeller shafts, impellers, and trolling wire. In marine environments, standard steel shafts would corrode, and standard stainless steel might succumb to pitting or fatigue. K-500 survives the dual attack of high torque load and corrosive saltwater. Note, however, that K-500 can be susceptible to stress corrosion cracking if used in slow-moving or stagnant seawater while under high applied stress; therefore, it is best utilized in high-velocity stream applications like rotating shafts.

The following diagram illustrates the typical applications of each alloy in a marine setting.

Related Q&A

Q1: Can I weld Monel K-500 using the same procedures as Monel 400?

No. While Monel 400 is easily weldable, Monel K-500 requires careful handling. Welding K-500 generally requires the annealed condition, and the finished assembly must be stress-relieved and age-hardened specifically to restore its high strength and ductility. Failure to heat treat can lead to cracking in the Heat Affected Zone (HAZ).

Q2: Which alloy is more expensive?

Monel K-500 is generally more expensive. This is due to the added alloying elements (Titanium and Aluminum) and the longer, more energy-intensive processing cycles (solution annealing and aging) required to produce it.

Q3: Is Monel 400 suitable for non-magnetic applications?

Generally, no. Monel 400 has a Curie point that fluctuates around room temperature. This means it can become magnetic on a cool day or if the composition varies slightly. For strict non-magnetic requirements (like gyroscope housings), Monel K-500 is the safer, reliable specification.