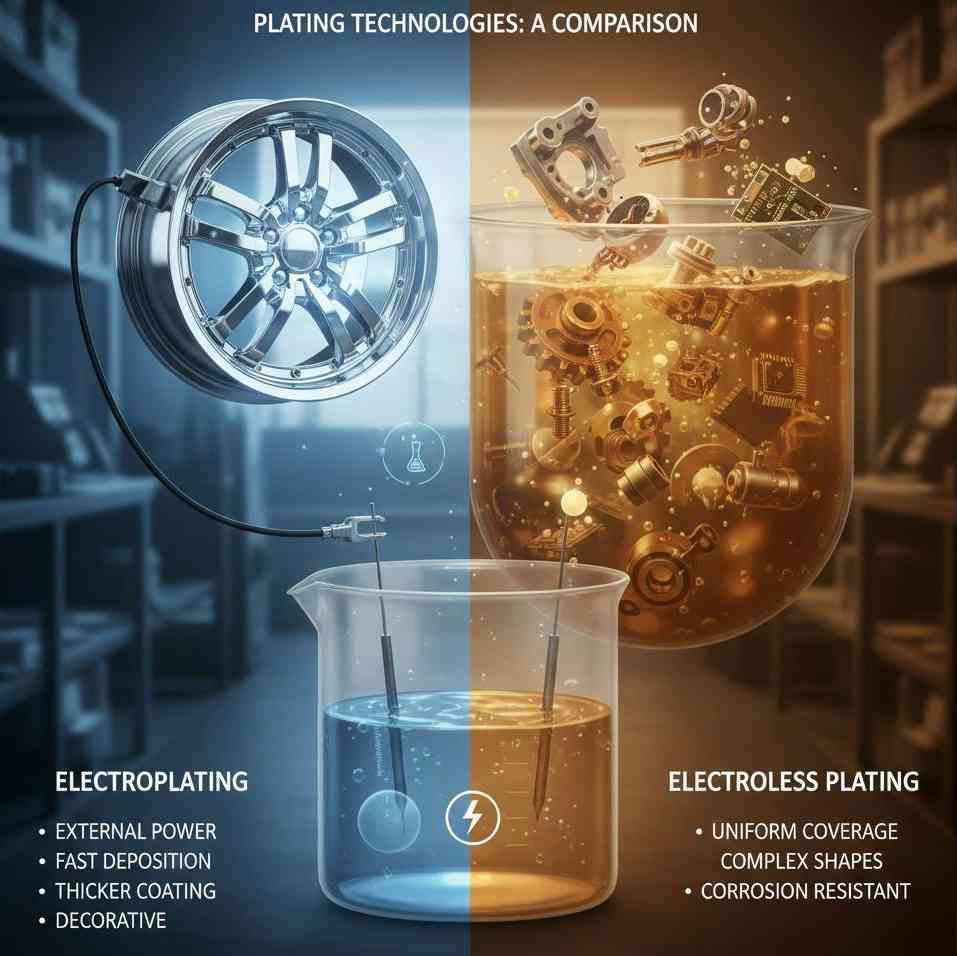

Electroless plating (Electroless Nickel Plating) is carried out through autocatalytic reduction, which is different from electroplating. Electroplating is performed by an external current due to the potential difference between the substrate and the medium. Essentially, there is no significant difference in the basic principle of film formation.

Electroless plating is mainly used for corrosion protection and decorative plating. It is widely applied to automobiles, bicycles, clocks, medical equipment, meters, instruments, and hardware. By using chemical action, a uniform film of nickel and/or other metals is deposited on the surface of black metal or non-ferrous metal. The film can be used for decorative plating, but it is mainly used for nickel strike, rust prevention, increasing wear resistance, brightness, and aesthetics. It is widely used in electronics, instruments, medical devices, fitness equipment, household items, and manufacturing industries. The electroless plating layer is uniform in thickness, and as long as the plating solution can permeate, the dissolution will be thorough and uniform, so it can achieve the ideal shape. Electroplating cannot fully cover complex workpieces, but electroless plating can be applied to workpieces of any shape. High-phosphorus electroless plating is amorphous, and the plating layer surface has no crystal boundaries, while electroplating is typically crystalline. Because electroplating requires external current, the deposition speed of electroplating nickel is much faster than that of electroless nickel, but the same thickness of the electroplating layer will need to be prepared earlier than the electroless plating layer. The bond strength of the electroless plating layer is generally higher than that of the electroplating layer. Electroless plating uses mostly food-grade additives, so using simple nickel salts or hypophosphite and other substances means electroless plating is more environmentally friendly than electroplating. Electroless plating currently only has one color, which is the color of a pure nickel alloy on the market, while electroplating can have many colors.

Electroless Nickel Plating and Electroplating Performance Comparison Table

| Coating property | Electroplated Nickel | Electroless (Chemical) Nickel |

|---|---|---|

| Composition | Contains Ni ≥ 99% | Avg. 92% Ni + 8% P |

| Structure | Crystalline | Amorphous |

| Density | Average | — |

| Coating uniformity | Variable | ±10% |

| Melting point (°C) | 1455 | ~890 |

| Hardness after plating (VHN) | 150–400 | 500–600 |

| Hardness after heat treatment (VHN) | Unchanged | 900–1000 |

| Wear resistance | Good | Excellent |

| Corrosion resistance | Good (coating has pores) | Excellent (coating nearly pore-free) |

| Relative magnetic permeability | 36 | 4 |

| Electrical resistivity (Ω·cm) | 7 | 60–100 |

| Thermal conductivity (W·m⁻¹K⁻¹) | — | ~ |

| Coefficient of linear expansion (K⁻¹) | — | — |

| Elastic modulus (MPa) | 207 | 69 |

| Elongation | — | 2% |

| Internal stress (MPa) | ±69 | ±69 |

| Friction behavior (relative to steel, dry condition) | Wear | — |

Related Q&A

Q1: Which coating gives better uniform coverage on complex parts — electroplated or electroless nickel?

A1: Electroless (chemical) nickel provides much more uniform, conformal coverage and can plate complex shapes evenly because it does not rely on an external electric field.

Q2: Which is harder — electroplated nickel or electroless nickel?

A2: As-plated hardness is typically higher for electroless nickel (500–600 VHN) compared with many electroplated layers (150–400 VHN). After heat treatment, electroless nickel hardness can increase further (900–1000 VHN).

Q3: Which coating is more corrosion resistant?

A3: Electroless nickel generally offers superior corrosion resistance because high-phosphorus electroless deposits are nearly pore-free, while electroplated coatings often contain pores that reduce corrosion resistance.

Q4: Are there trade-offs between electrical conductivity and corrosion resistance?

A4: Yes. Electroplated nickel (high Ni content) has much lower electrical resistivity (~7 Ω·cm in the table) than electroless nickel (60–100 Ω·cm), but electroless nickel typically provides better corrosion resistance and wear performance due to its composition and microstructure.