Engineers choosing materials for demanding environments increasingly rely on nickel and nickel alloys because of their unique combination of strength, creep resistance, and corrosion performance. This article consolidates the engineering properties of nickel and nickel alloys in a single practical reference — emphasizing what matters for component design, fabrication, and long-term service in both corrosive and high-temperature settings.

1. Fundamental physical and metallurgical traits

Nickel has a face-centered cubic (FCC) crystal structure at room temperature, which contributes to good ductility and toughness. Key baseline traits that drive the broader engineering properties of nickel and nickel alloys include:

-

High cohesion and a relatively high melting point (~1455 °C), enabling elevated temperature use.

-

Good toughness and fracture resistance in cryogenic-to-moderate temperatures due to FCC symmetry.

-

Ability to form protective passive films (when alloyed with chromium) that improve corrosion resistance.

These baseline attributes make pure nickel and its alloys versatile for aerospace, chemical processing, marine, and power-generation applications.

2. Mechanical properties: strength, ductility, toughness

The mechanical spectrum of nickel-base materials covers soft, ductile nickel through precipitation-hardened superalloys:

-

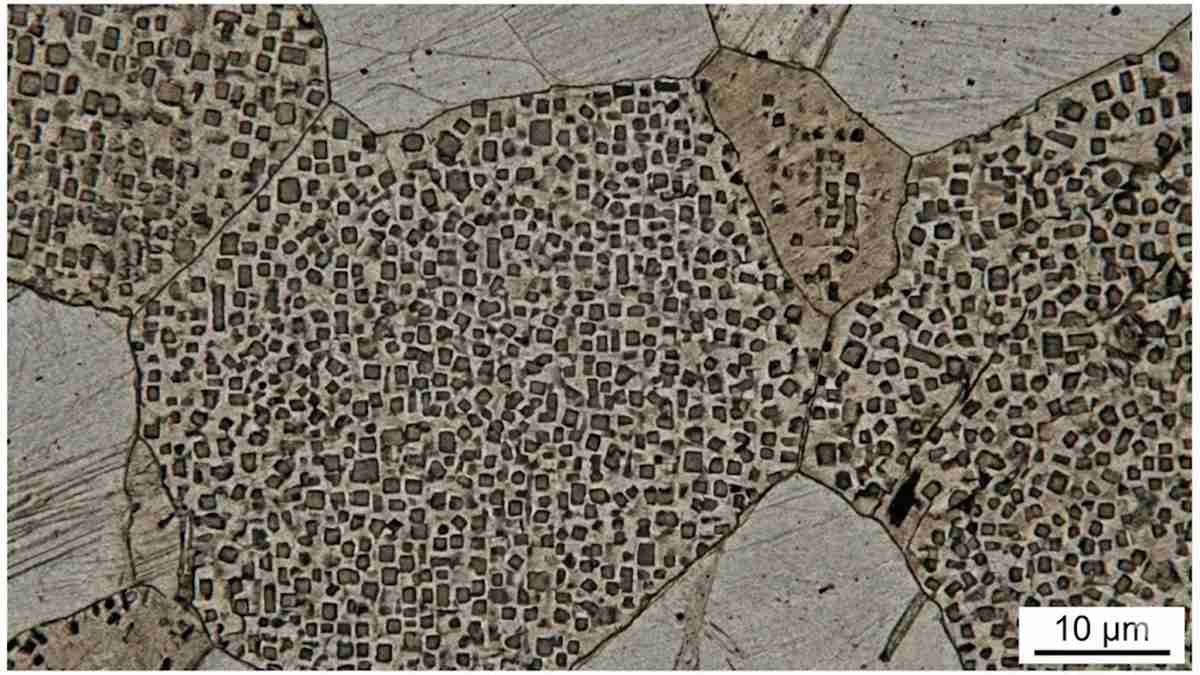

Strength & yield behavior: Nickel alloys can be tailored from low-strength, easily formed grades to very high-strength superalloys via alloying and heat treatment. Precipitation hardening (e.g., γ′ Ni₃(Al,Ti)) and solid-solution strengthening (Cr, Mo, Co) are primary mechanisms.

-

Ductility & toughness: Due to FCC structure, many nickel alloys retain ductility even at low temperatures. Toughness is excellent in wrought alloys; cast and heavily alloyed materials may be less forgiving and require attention to casting defects.

-

Fatigue & fracture: High-cycle fatigue performance depends on surface finish and microstructure; nickel superalloys used in rotating components are engineered for long fatigue life through controlled grain size and precipitate distributions.

3. High-temperature performance and creep resistance

One of the defining engineering properties of nickel and nickel alloys is sustained strength at elevated temperatures:

-

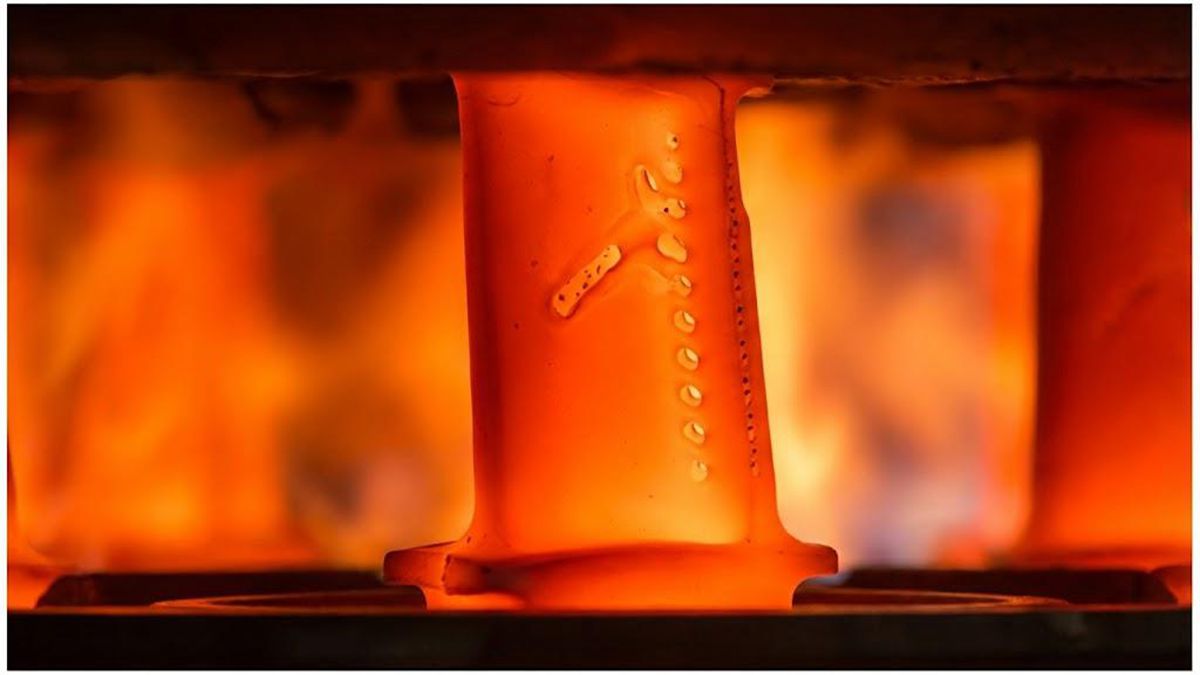

Creep resistance: Nickel-based superalloys (e.g., Inconel, Nimonic family) derive creep strength from ordered γ′ precipitates and stable grain structures. These alloys are widely used in turbine discs, combustor liners, and exhaust systems where creep life determines service life.

-

Oxidation and scale behavior: Alloying with chromium, aluminum, and silicon improves protective oxide formation, reducing high-temperature oxidation and hot corrosion. Selection balances protective scale formation vs. mechanical property requirements.

4. Corrosion resistance and environmental behavior

Corrosion resistance is one of the most leveraged engineering properties of nickel and nickel alloys:

-

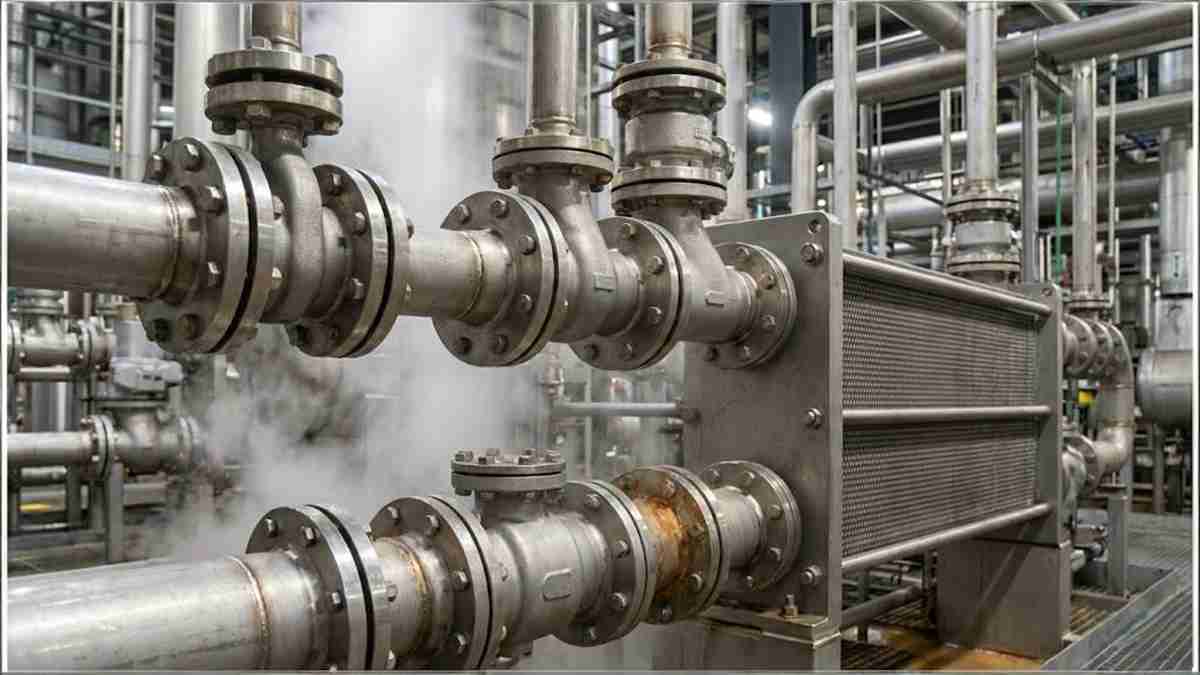

General corrosion: Many nickel alloys resist general aqueous corrosion; copper-nickel alloys (Monel) do particularly well in seawater.

-

Localized corrosion and pitting: Adding molybdenum and chromium reduces susceptibility to pitting in chloride environments. Hastelloy and selected Inconel/Incoloy grades are chosen for aggressive chemical plants.

-

Stress corrosion cracking (SCC): Some nickel alloys are less susceptible to SCC than stainless steels, but susceptibility still depends on composition, heat treatment, and residual stresses.

5. Fabrication, joining, and machinability

-

Forming & cold work: Wrought nickel alloys are workable but often work-harden; intermediate anneals may be required. Formability declines with higher alloy additions and precipitation-hardened conditions.

-

Machining: Many nickel alloys are challenging to machine (tendency to work-harden, low thermal conductivity). Best practice: rigid tooling, interrupted cuts, carbide inserts, and optimized coolant strategies.

-

Welding and joining: Nickel alloys generally weld well with appropriate filler metals and pre/post-weld heat treatments. Some high-strength superalloys require specialized procedures to avoid hot cracking and preserve mechanical performance.

6. Heat treatment and strengthening mechanisms

Key routes to tune engineering properties of nickel and nickel alloys:

-

Solid solution strengthening: Alloying with Cr, Mo, Fe, Co.

-

Precipitation strengthening: Controlled aging to form γ′ or γ″ precipitates in superalloys.

-

Work hardening and annealing: Used for wrought products to set ductility/toughness balance.

Understanding these mechanisms helps engineers specify temper, heat treatment schedules, and inspection points.

7. Selection guidelines — matching properties to service

When specifying based on the engineering properties of nickel and nickel alloys, consider:

-

Operating temperature and creep life (use nickel superalloys above ~600–700 °C where steels soften).

-

Corrosive species and pitting risk (select Mo-bearing Hastelloy or high-Cr Inconel for chlorides/acid service).

-

Fabrication route (cast vs wrought, ease of machining, weldability).

-

Cost and availability (nickel and specialty alloys are more expensive — use only where performance justifies cost).

8. Testing, standards and quality control

Designers should require material certifications and standardized testing (tensile, creep, fatigue, pitting corrosion tests) per ASTM/ISO specifications. Microstructural check (metallography) following welding or heat treatment is often mandatory for critical components.

The engineering properties of nickel and nickel alloys make them indispensable where a durable combination of high-temperature strength, corrosion resistance, and toughness is required. Proper alloy selection, heat treatment, and fabrication practice unlock their full potential for demanding industrial applications.

FAQs

-

Q: What are the best nickel alloys for high-temperature creep resistance?

A: Nickel-base superalloys (Inconel, Nimonic families) with γ′ precipitation and controlled grain structures are the typical choice. Select grades based on temperature, stress, and oxidation environment. -

Q: Are nickel alloys better than stainless steels for corrosive environments?

A: It depends. For many highly aggressive chemical environments (chlorides, acids), Ni-Mo or Ni-Cr-Mo alloys (Hastelloy, some Inconel grades) outperform stainless steels. For mild environments, stainless steels may be more cost-effective. -

Q: How should I approach machining or welding nickel alloys?

A: Use rigid setups, sharp carbide tooling, controlled feeds to avoid work hardening, and qualified welding procedures with proper filler metals and PWHT (post-weld heat treatment) for high-strength grades.