When selecting materials for extreme environments, the distinction between Inconel 600 and Incoloy 800 often determines the longevity and safety of the equipment. While both are high-performance nickel-based alloys, they belong to different metallurgical families with distinct strengths. Understanding the specific chemical interactions—particularly regarding nickel content—is vital for engineers and procurement managers.

This guide analyzes the critical differences, selection criteria, and specific applications in furnace tubing.

Inconel 600 vs Incoloy 800 comparison

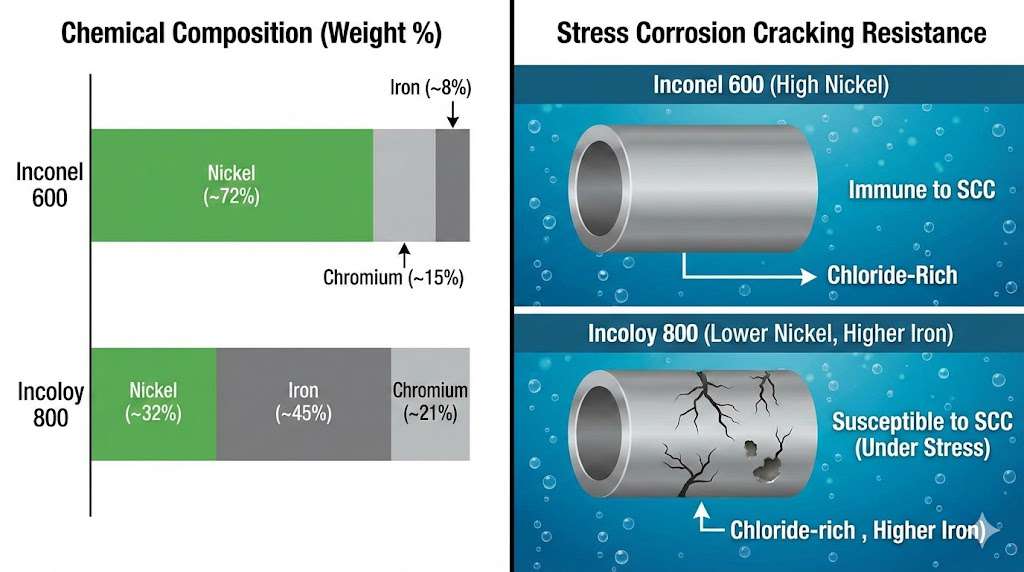

The fundamental difference lies in their composition and the resulting resistance profile.

-

Inconel 600 (UNS N06600) is a Nickel-Chromium-Iron alloy. Its defining feature is a high nickel content (minimum 72%).

-

Incoloy 800 (UNS N08800) is a Nickel-Iron-Chromium alloy. It contains significantly less nickel (30-35%) and much higher iron (39.5% min).

1. Corrosion and Stress Corrosion Cracking (SCC) The 72% nickel content in Inconel 600 makes it virtually immune to Chloride-Ion Stress Corrosion Cracking. This makes it the superior choice for environments containing magnesium chloride or other salts. Incoloy 800 offers moderate resistance to SCC—far better than 300-series stainless steels—but can still crack under extreme cyclic stress in chloride environments.

2. Oxidation vs. Sulfidation Both alloys utilize chromium to form a protective oxide layer, providing excellent oxidation resistance. However, Incoloy 800 outperforms Inconel 600 in sulfur-bearing environments. High-nickel alloys like Inconel 600 are susceptible to “sulfidation” (sulfur attack) at high temperatures, which causes rapid embrittlement. The iron-heavy matrix of Incoloy 800 mitigates this risk.

3. Cost Efficiency Nickel is an expensive commodity. Due to its lower nickel composition, Incoloy 800 is significantly more cost-effective than Inconel 600. For applications where the extreme properties of Inconel 600 are not strictly required, Incoloy 800 is the industry standard for economic efficiency.

The following image illustrates the key differences in composition and resistance to stress corrosion cracking.

Figure 1: A comparison of chemical composition and its effect on Stress Corrosion Cracking (SCC) resistance in chloride environments.

Inconel 600 vs Incoloy 800 how to choose

Selecting between these two alloys requires a technical evaluation of the operating environment. Use this decision framework:

Choose Inconel 600 if:

-

The environment is “Reducing”: Inconel 600 excels in reducing environments where oxidation is not the primary mode of attack.

-

Nitriding is a threat: In nitrogen-based atmospheres (e.g., ammonia crackers), Inconel 600 resists nitrogen embrittlement better than iron-based alloys.

-

Chloride exposure is extreme: If the process fluid contains high levels of chlorides that would crack Incoloy 800, the premium for Inconel 600 is justified.

-

Temperature exceeds 1100°C (2000°F): Inconel 600 retains better structural integrity at the very upper limits of heat treating.

Choose Incoloy 800 (or 800H/HT) if:

-

Sulfur is present: In sour gas or fuel-oil fired environments, Inconel 600 will deteriorate quickly.

-

Creep strength is priority: For prolonged exposure to high temperatures (above 816°C), the controlled carbon versions—Incoloy 800H/HT—offer superior creep and rupture strength compared to standard Inconel 600.

-

Budget is a constraint: Incoloy 800 provides the best cost-to-performance ratio for general high-temperature oxidation resistance.

Inconel 600 vs Incoloy 800 for furnace tubing

Furnace tubing represents the most common battleground for these two materials. The choice depends heavily on the internal process fluid and the external heating method.

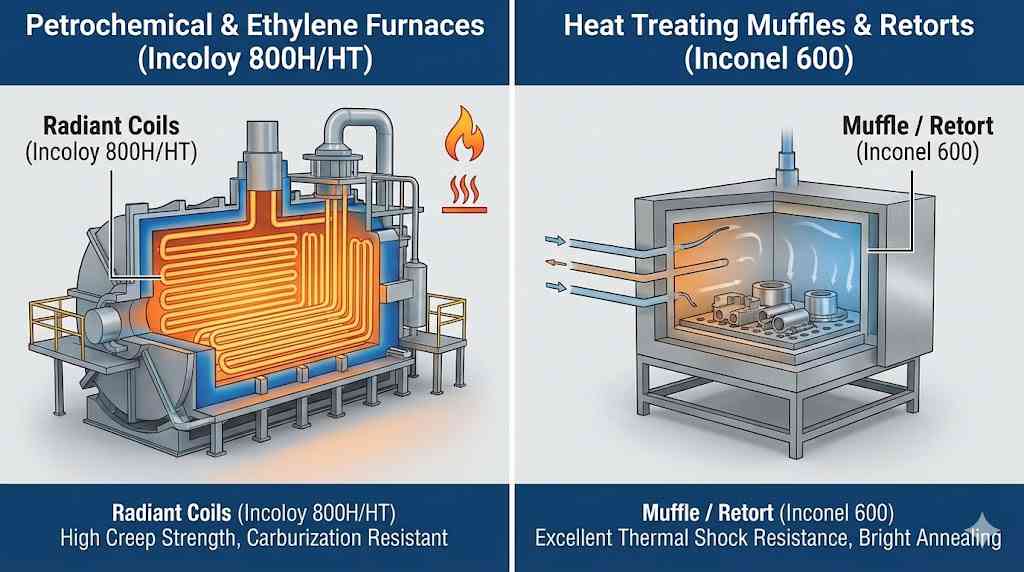

Petrochemical & Ethylene Furnaces (The 800H/HT Domain) In the petrochemical industry, particularly for ethylene cracking and steam methane reforming (SMR), Incoloy 800H/HT is the standard material for convection and radiant coils. The alloy’s balance of creep strength and resistance to carburization allows it to withstand the thermal cycling of decoking processes without the prohibitive cost of high-nickel alternatives.

Heat Treating Muffles & Retorts (The Inconel 600 Domain) Inconel 600 is frequently used for furnace muffles, retorts, and baskets in heat-treating facilities.

-

Carburizing Furnaces: While 800 resists carburization, 600 is often preferred for fixtures because it resists the “metal dusting” phenomenon and thermal fatigue in batch processes.

-

Bright Annealing: For bright annealing of stainless steel strips in hydrogen atmospheres, Inconel 600 tubing ensures the purity of the atmosphere is maintained without surface degradation.

The following diagram provides a visual guide to common furnace tubing applications for each alloy.

Figure 2: Typical furnace tubing applications, showing Incoloy 800H/HT in a petrochemical furnace and Inconel 600 in a heat-treating muffle.

Related Q&A

Q1: Can Incoloy 800 be welded to Inconel 600?

Yes. Dissimilar welding is common. A high-nickel filler metal, such as Inconel 82 (ERNiCr-3) or Inconel 182, is typically used to ensure the weld joint retains corrosion resistance and ductility matching the superior base metal (Inconel 600).

Q2: Which alloy handles thermal shock better?

Generally, Inconel 600 handles thermal shock slightly better due to its lower coefficient of thermal expansion compared to the iron-rich Incoloy 800. This reduces stress during rapid heating and cooling cycles.

Q3: Are Inconel 600 and Incoloy 800 magnetic?

Inconel 600 is non-magnetic at room temperature. Incoloy 800 is also generally non-magnetic, but because it contains more iron, it may develop slight magnetic permeability after cold working or welding, whereas 600 remains stable.