Nickel Alloy News

Nickel alloy news and industry knowledge

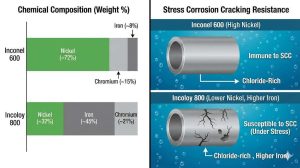

Inconel 600 vs Incoloy 800

When selecting materials for extreme environments, the distinction between Inconel 600 and Incoloy 800 often determines the longevity and safety of the equipment. While both

Inconel 600 vs Inconel 601

In the realm of superalloys, the Nickel-Chromium-Iron family remains the gold standard for environments requiring extreme heat and corrosion resistance. Among these, Inconel 600 (UNS

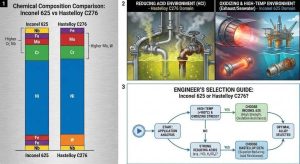

Inconel 625 vs Hastelloy C276

When selecting materials for extreme environments, the decision often narrows down to two titans of the nickel-alloy world: Inconel 625 and Hastelloy C276. Both are

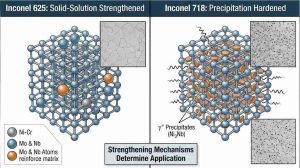

Inconel 625 vs Inconel 718

In the realm of extreme metallurgy, Inconel 625 and Inconel 718 stand as the industry standards for nickel-based superalloys. While they share a base composition

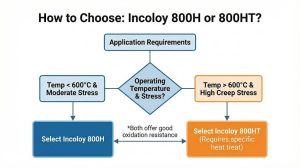

Incoloy 800H vs Incoloy 800HT

This article gives a focused, engineer-level comparison of Incoloy 800H vs 800HT, explains how to choose between them for high-temperature service, and breaks down 800H

Incoloy 800 vs Incoloy 800H

When engineers evaluate corrosion-resistant nickel-iron-chromium alloys for elevated-temperature service, the recurring comparison is Incoloy 800 vs Incoloy 800H. Although both alloys share the same base

Customer Reviews